Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

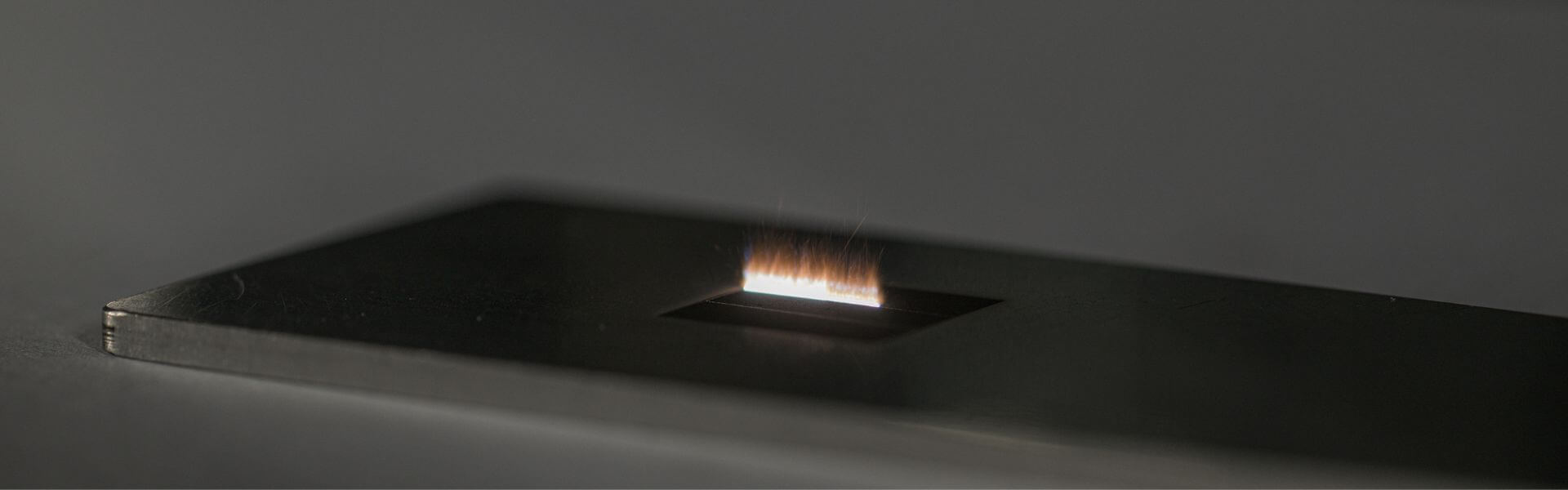

For changing the surface topology or its properties, the laser enables many applications, such as laser ablation, laser structuring, laser cleaning or laser marking. The decisive advantages over conventional methods are the contactless and forceless effect of the laser radiation as well as the precise energy input. Due to our large number of different laser sources, we at BBW Lasertechnik can respond individually to your customer enquiry for surface processing.

The different possibilities of surface processing with the laser cannot be classified together as a manufacturing process according to DIN 8580. While laser ablation and structuring remove material from the workpieces, laser cleaning does not process the base material, but merely removes unwanted and foreign material. In the case of laser marking, material is either ablated or not (e.g., in the case of annealing marking), depending on the type of laser marking.

In surface processing, as little or no material as possible should be transferred into the molten state, but directly into a gaseous state. This can be achieved with the rule of thumb "shorter exposure time + higher radiation intensity". Pulsed laser systems with laser pulses in the nanosecond range, or even shorter, are used for this purpose.

Pulse repetition rates in the MHz range are also possible with systems that emit laser pulses in the nanosecond range or even shorter. Best is the shortest possible pulse in the femtosecond range, where there is complete sublimation or vaporisation of the affected zone and no heat conduction. With pulses in the nanosecond range, melting components and heat conduction effects are present, but the surface processing rate is significantly higher with these systems.

Materials that are surface processed with the laser must be able to absorb energy of the appropriate laser wavelength. This is the case for most non-transparent materials such as metals - e.g. aluminum, copper and stainless steel - certain plastics, but also wood. If an ultra-short pulsed laser system is used for a machining process, the material dependency is completely eliminated due to the occurrence of non-linear effects - even transparent materials such as glass or even ceramics can be processed with it.

Our material stock contains several hundred different materials as standard, which guarantees the shortest possible delivery times. For special materials we cooperate with efficient suppliers and also the provision of materials as raw material or as pre-processed product is implemented in our processes as standard.

Products

Applications

Our laser surface processing capabilities enable a wide range of applications. Below are a few examples:

More application examples