Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

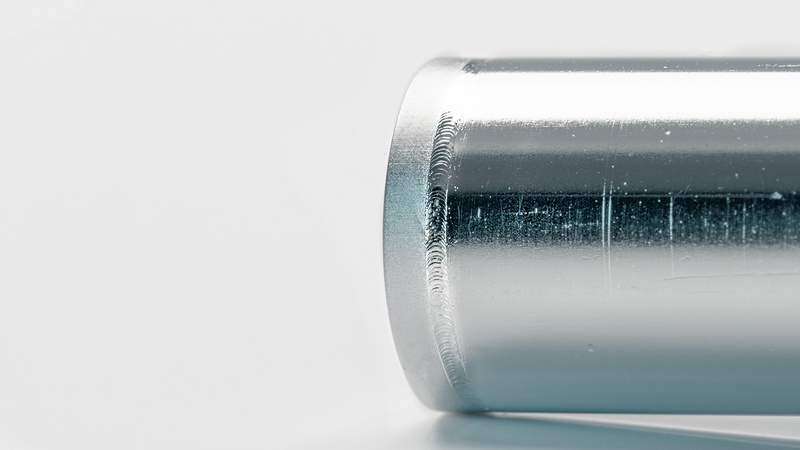

Micro welding – also known as precision welding – follows the trend of increasing miniaturisation in welding. Requirements with regards to precision have increased significantly in recent years.

The advantages of using lasers to weld are especially evident in micro welding. For this reason, micro welding offers a good alternative to resistance welding and soldering. With this method, the application of energy can be controlled with extreme precision. The two main advantages are a very small heat-affected zone, and therefore less potential for distortion.

Micro welding involves penetration depths of < 1 mm. The parts that are welded are also typically just millimetres in size. Even incredibly thin-walled components down to 0.03 mm can be welded with this process. Pulsed Nd:YAG or fibre lasers are usually used for micro welding. In micro welding, hitting the positions with incredible precision requires positioning accuracy and repeat precision.

Micro welding is especially used in the electronics and medical technology industries. In electronics, stainless steel and copper alloys often require welding, and mixed welds are becoming more and more common. Stainless steel and titanium are often used in medical technology applications.

See also: Precision Laser Cutting, USP Laser Processing