Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

The aim of laser structuring is not to remove material to a certain depth, but to create regular structures to change the surface properties. The elements of these structures are sometimes only single micrometres in size. Examples include changing the surface roughness, increasing the adhesive strength for adhesive surfaces or the tendency of the material to repel or absorb water.

Short-pulsed or ultra-short-pulsed systems are used for surface structuring. The shorter the pulse, the lower the heat influence on the component. With ultrashort pulses, one finally speaks of cold laser processing - due to the lack of heat conduction. Here as well, productivity is higher using short-pulsed radiation, while even more detailed structures are possible using ultra-short-pulsed laser radiation. The latter, however, requires the use of more complex positioning systems.

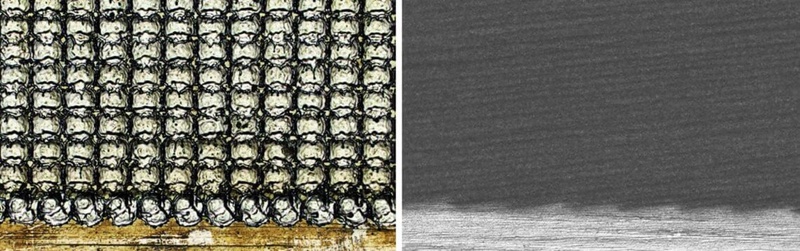

Comparison of laser structuring and laser cleaning

The good adhesive strength of a bonded joint is counteracted on the one hand by surfaces with low roughness and on the other hand by unwanted passive layers. Targeted structuring removes the counterproductive passive layer (e.g., of stainless steel) and increases the average roughness and thus also the usable total surface for the bonded joint.