Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

Ultra-short pulse lasers are always used in material processing when accuracies in the range of 1 µm are required or the heat input must be reduced to a minimum. In order to use the advantages of ultrashort laser pulses, correspondingly precise positioning systems are required. The UKP lasers used today are usually free-beam ultrashort pulse lasers. However, the higher accuracies are at the expense of productivity, which is why short-pulse lasers are used wherever possible for economic reasons.

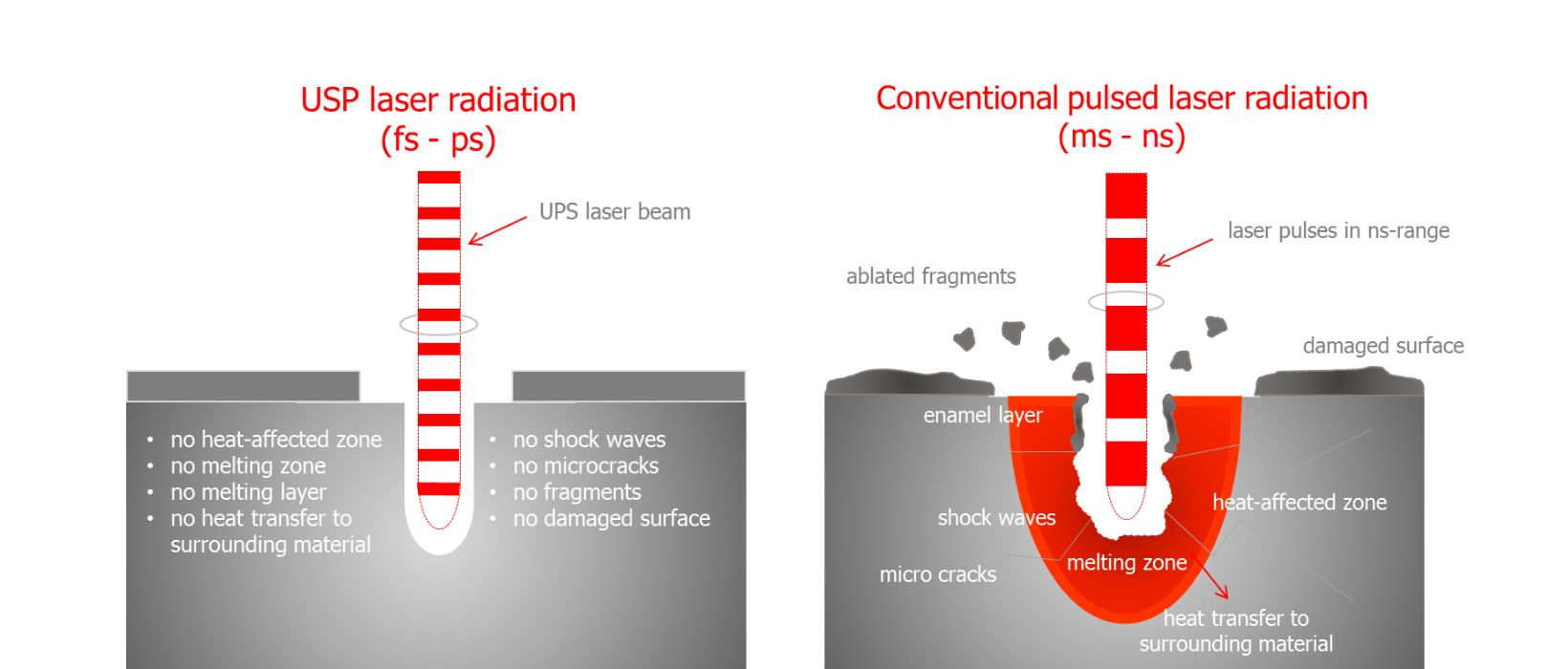

In UKP laser processing, the energy density is so high due to the short pulse duration that localised sublimation occurs. Adjacent material areas are hardly (ps pulse) or not at all (fs pulse) thermally affected, which means that a very high surface quality can be achieved due to the melt formation that is avoided. Machining with UKP lasers is therefore also known as "cold ablation".

The use of UKP lasers also allows a greater variety of materials to be processed than with short-pulse lasers. Due to the high intensities of the extremely short laser pulses, non-linear effects occur during the interaction of laser radiation and material, such as multiphoton absorption. This means that almost all materials can be processed.

The range of applications extends from micro-structuring, fine cutting, the creation of micro-holes to the functionalisation of surfaces. Another advantage of UKP laser radiation is the occurrence of non-linear effects, which means that practically any material can be processed.

BBW Lasertechnik also offers the innovative processing option with ultra-short pulse lasers.