Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

In laser ablation, material is selectively removed by the laser beam, which also creates three-dimensional and detailed depressions. It is also possible to selectively remove layers applied to the base material. Generally, the processing is carried out "pulse by pulse": In the area of interaction between the laser spot and the material, a crater with the dimensions of the laser beam spot diameter and to a depth of a few micrometres is created with each pulse. Depending on the pulse duration and beam intensity, the material is completely vaporised or partially melted. The shorter the pulse duration, the lower the heat input into the component. With sufficient pulse overlap, this results in a coherent surface ablation.

The surface to be processed is ablated layer by layer to the final contour via a highly dynamic scanner optic. Due to the short pulse duration, the energy density of USP laser processing is so high that sublimation is locally limited. Adjacent material areas are hardly (ps pulse) or not (fs pulse) thermally influenced, which means that a very high surface quality can be achieved due to the melt formation that is avoided. Machining with USP lasers is therefore also known as "cold ablation". Another advantage of USP laser radiation is the occurrence of non-linear effects, which means that practically any material can be machined.

Short pulse machining (ns pulse), on the other hand, has the advantage of a significantly higher area ablation rate since the lasers available on the market allow significantly higher pulse energies at a comparable pulse repetition rate. At the same time, however, not all materials can be processed and the increased heat input into the component must be considered.

While the use of short-pulsed laser radiation achieves accuracies of about 0.01 mm, we can realise accuracies of up to 0.001 mm by using USP lasers and thus meet even the highest requirements.

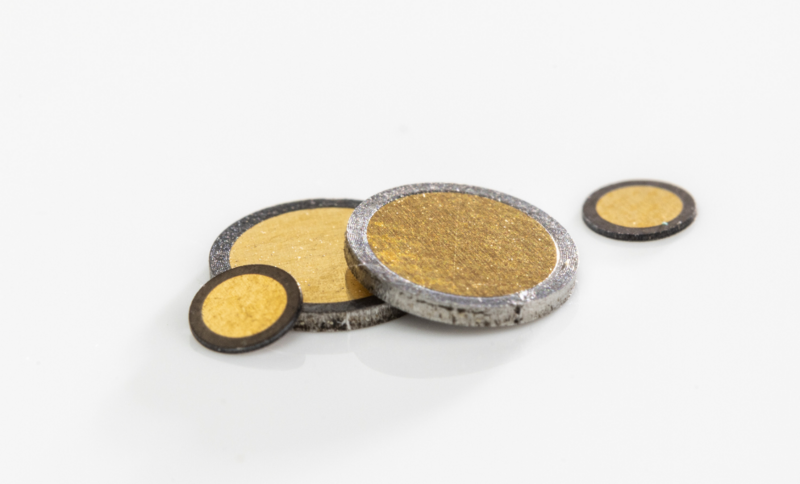

The ablation rate (= ablation volume per laser pulse) by USP laser radiation depends on the material to be ablated and the laser parameters. For many combinations, such as lacquer coatings on a metal, a highly selective ablation process is possible, as lacquer coatings can be ablated with a volume-aspect ratio of 20:1 or more compared to the metal base surface.

Laser ablation is frequently used in tool and mould making as well as in semiconductor technology. At BBW Lasertechnik, this process is used, for example, in the decoating of copper cables or the stripping of paint from housing components.