Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

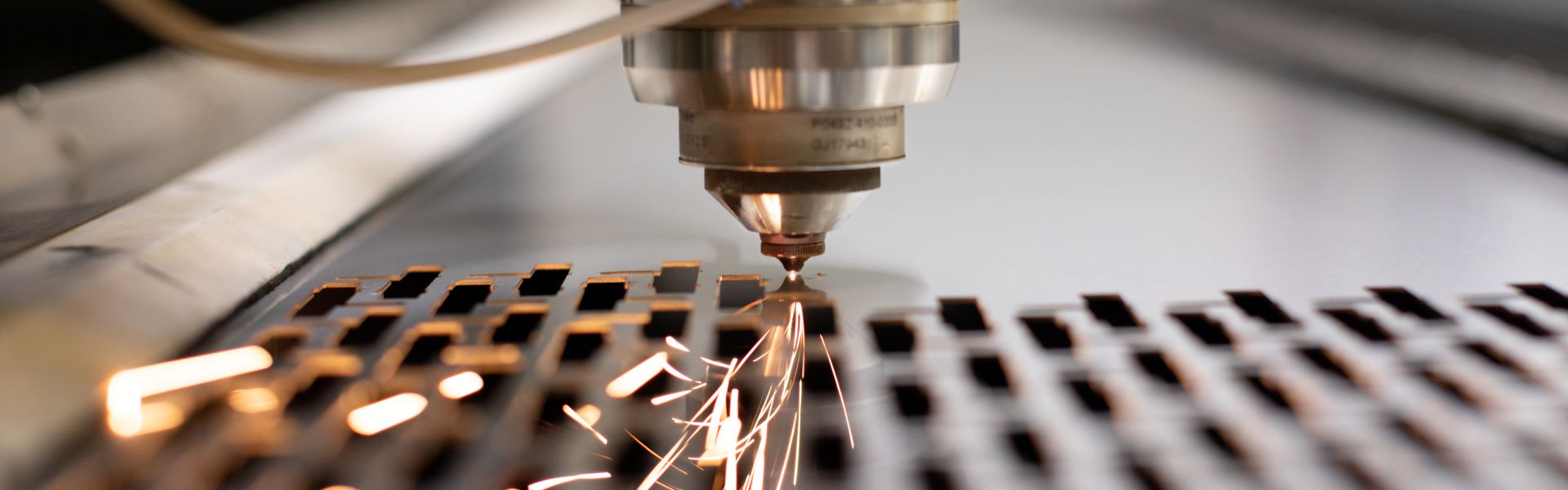

Laser cutting is one of the most important laser technology applications. With our nine systems, we can react flexibly to meet our customers’ requirements.

The greatest advantage of laser cutting is its high degree of flexibility. Even a batch size of just one can be produced economically in any geometry thanks to our laser cutting services. Further advantages include a narrow kerf and the high quality of the cut, which often eliminates the need for reworking.

At BBW Lasertechnik, we can offer a wide variety of laser cutting options. To produce individual pieces for (sheet metal) assemblies, we have two 2D flatbed cutting machines with a capacity of up to 6 kW, each of which is connected to a highly efficient automated sheet metal storage system. Our CO2 laser is used for laser cutting services with more stringent requirements on the quality of the kerf, and we take advantage of the beneficial wavelength of our disc laser when laser cutting copper and aluminium.

Additionally, we offer 3D laser cutting services that can process complex geometries with pieces up to 4 metres long, from individual units to large-scale production.

One focus of laser cutting with BBW Lasertechnik is on precision laser cutting – the processing and production of especially thin, filigree geometries with component thicknesses down to 0.01 mm. We use systems we optimise ourselves for this type of laser cutting work. If you would like to learn more about this service, please visit our fine laser cutting page.

Laser cutting has a wide range of applications; we process orders on behalf of the aerospace industry, automotive industry and food industry, as well as medical technology applications, for instance.

Note: For the complete production of (complex) assemblies, we offer laser cutting in different variants. For pure laser-cut parts, we have specialized in precision laser cutting below 0.5 mm.