Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

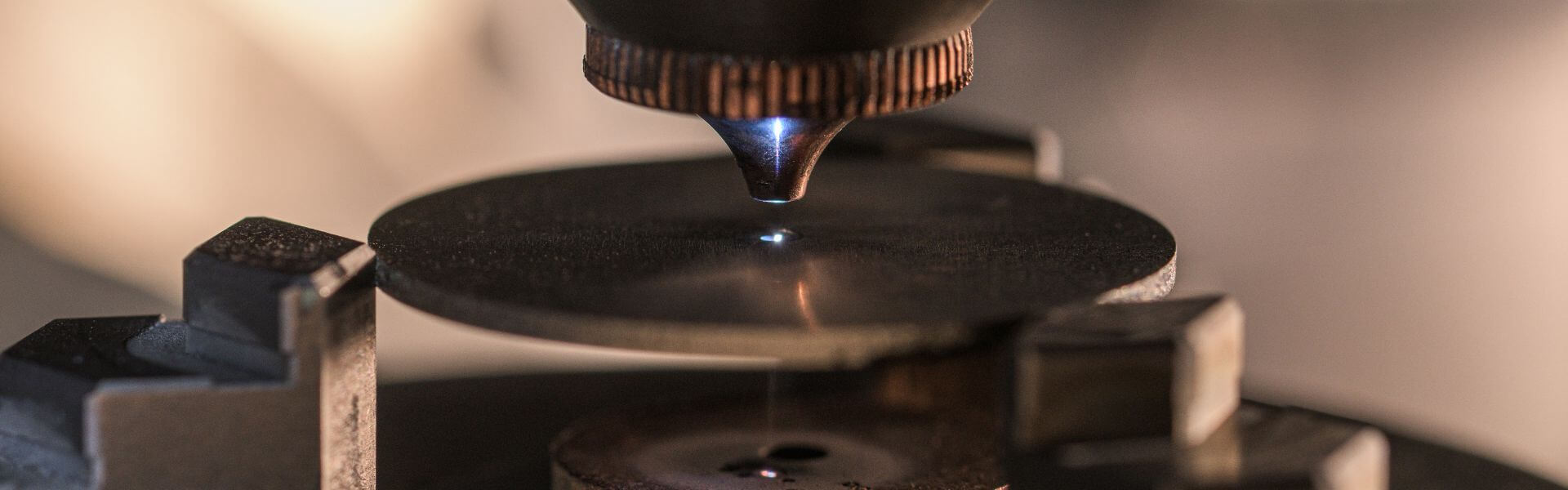

In addition to laser welding and cutting, laser drilling and micro drilling are among our specialties. With our systems, we can achieve the finest bores – at rates of up to 50 per second.

Compared to conventional drilling techniques, laser drilling has a number of advantages. One is the contactless processing, eliminating any additional pressure on a component. Compared to conventional drilling, there is no wear on the tools used; plus, laser drilling is reliable and excellent for automation. Its advantageous and precise energy input leads to minimal heat stress on components, meaning no coolant is required. The biggest strength of laser drilling, however, is in the production of the finest bores that would not be possible by mechanical means.

Depending on requirements, we choose the best combination of beam source, systems engineering and parameters. With our laser drilling systems, we can achieve bore diameters down to 50 µm with depths of 0.5 mm. Our maximum depth is 15 mm with a maximum diameter of around 0.15 mm. For the greatest productivity we rely on single pulse drilling, which produces up to 50 bores per second. This process is especially suitable for the production of filters. Drilling angles of up to 20° make laser drilling possible in even difficult-to-reach places.

To achieve even more precise results in micro-machining, we recommend our systems with USP-technology.

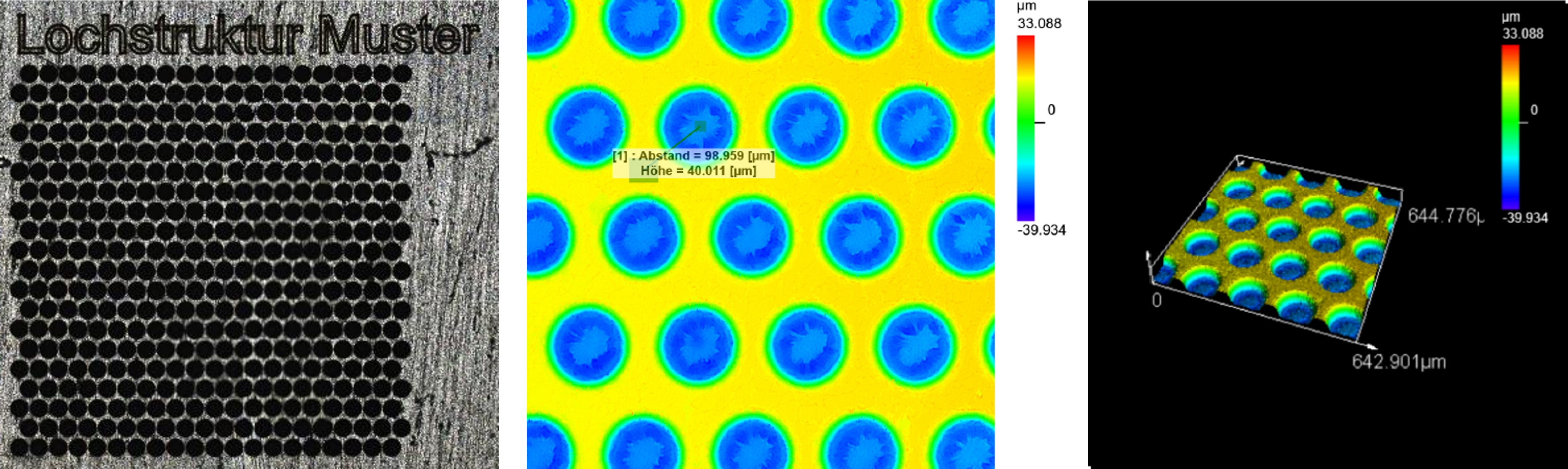

Blind hole drilling with a depth of 40 µm