Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

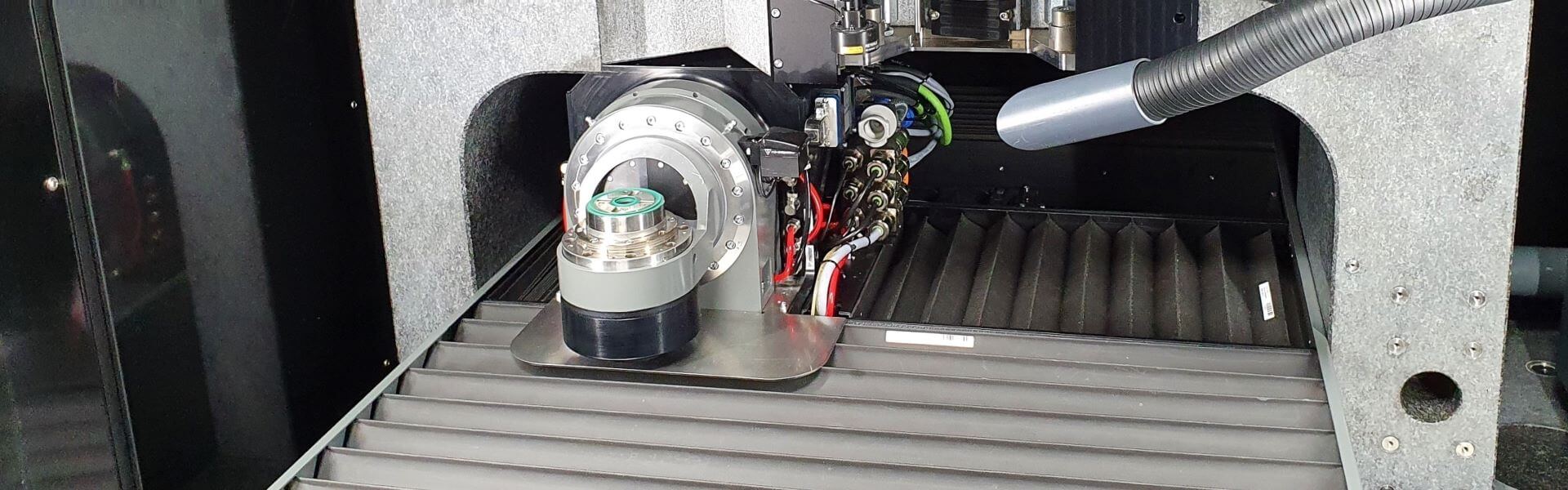

We have been in the fine cutting business for more than 20 years. Since the machining accuracy of µs pulses is limited due to the process, we also offer an innovative processing option with the use of ultrashort pulse lasers.

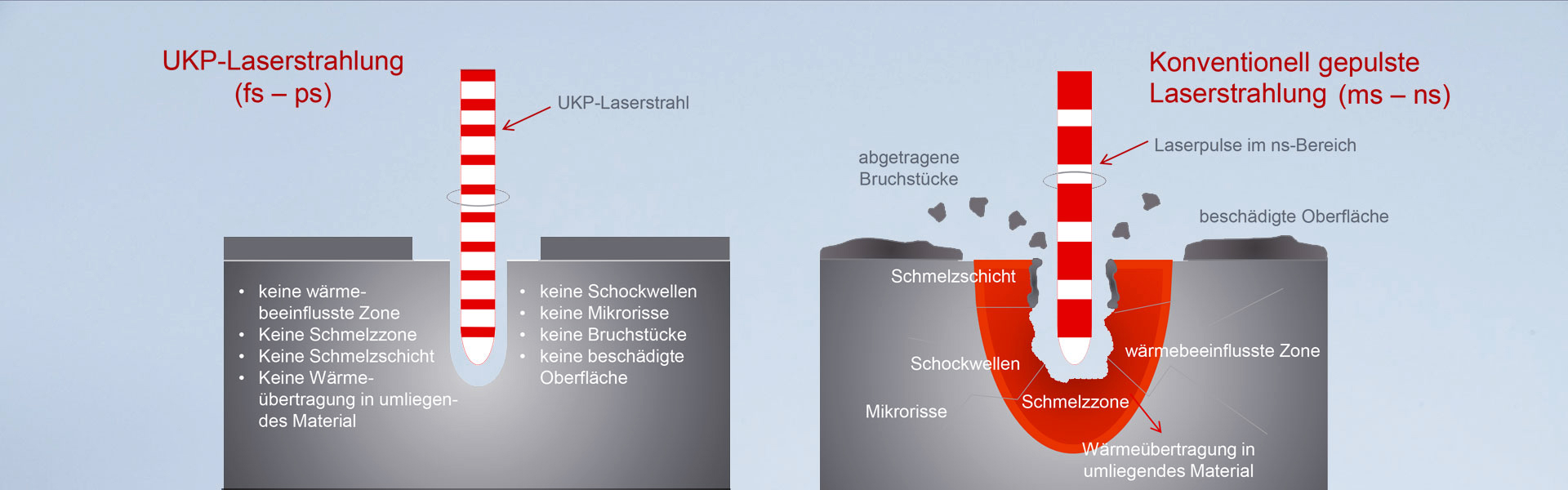

Because of the very short duration of the pulse, ultra short pulse (USP) laser processing features energy density so high that it leads to localised sublimation. Surrounding areas undergo hardly any thermal influence (ps-pulse), if at all (fs-pulse). Because the formation of molten metal is not formed in this process, a very high surface quality can be achieved. Ultrashort pulse laser work is therefore also known as “cold erosion”.

Applications range from micro structuring, precision cutting and micro drilling to the functionalisation of surfaces. Another advantage of USP lasers is the occurrence of nonlinear effects, allowing virtually any material to be processed.

With localised sublimation of the material, the molten state is skipped and the material enters directly into the gas phase, or into a plasma state. This prevents residues from depositing on the cutting or drilling edge, negatively affecting the geometry created. Compared to machining with conventional pulsed laser radiation, USP laser processing allows for more precise cutting and borehole geometry.

Using a highly dynamic scanner optic, the surface in question is stripped layer by layer until it reaches its final contour. Ultrashort laser pulses in the femtosecond range in particular can create reproducible accuracies in the µm range due to the insignificant thermal influence.

With the right choice of parameters, extremely high-contrast and dark markings can be realized on a material surface without removing material. Here, ultrashort laser pulses are used to create structures in the nanometer range, which act like a light trap for incident light. The result is a deep black and corrosion-resistant marking, even on materials such as aluminum.

The ablation rate (= ablation volume per laser pulse) by USP laser radiation depends on the material to be ablated and the laser parameters. For many combinations, such as paint layers on a metal, a highly selective ablation process is possible, since paint layers with a volume-aspect ratio of 20:1 or more compared to the metal base can be ablated.

Processable material thickness values with USP

Hole diameter with USP