BBW Lasertechnik GmbH

Phone: (0 80 36) 9 08 20- 0

Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

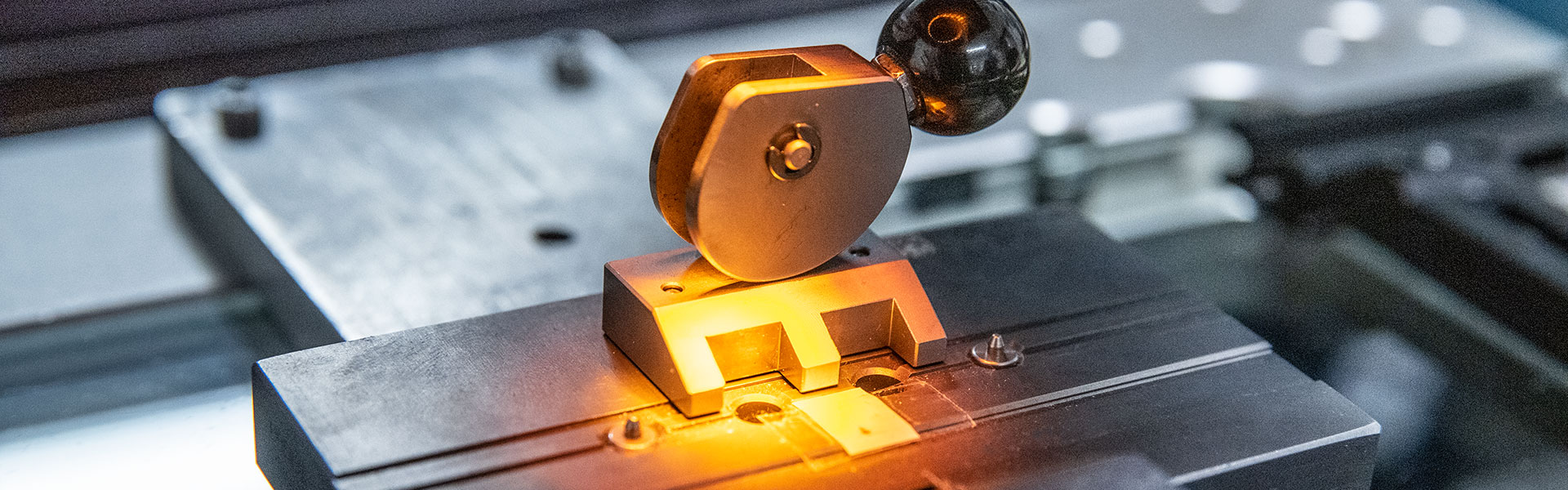

Customer satisfaction is the number one priority at BBW Lasertechnik. To ensure the highest satisfaction in our laser welding, cutting and drilling services, we rely on comprehensive quality management including state-of-the-art system and process engineering.