BBW Lasertechnik GmbH

Phone: (0 80 36) 9 08 20- 0

Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

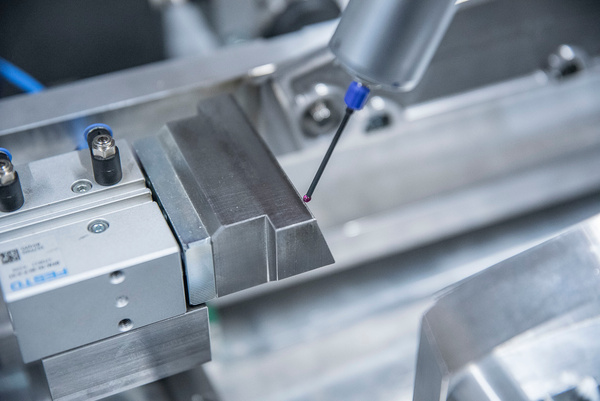

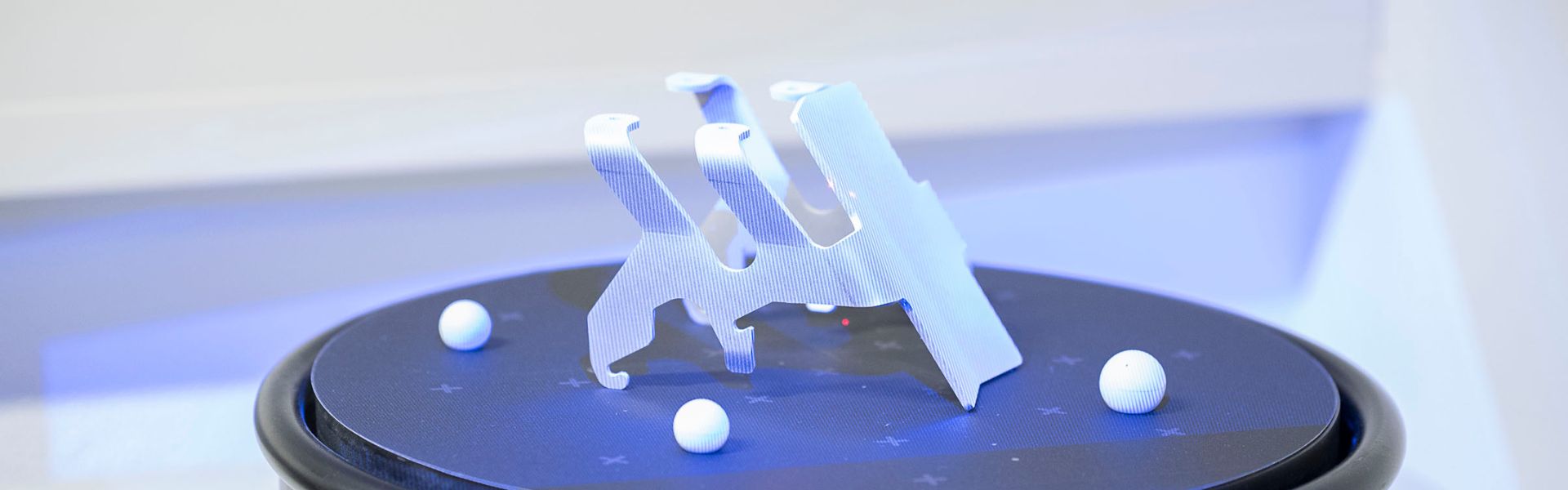

At BBW Lasertechnik, our focus is not only on innovative technology, but also on the best possible quality assurance. We act proactively to identify and minimize potential risks during the production process. We understand that the reliability of our services is crucial to the success of our customers. For this reason, we rely on comprehensive quality assurance measures.