BBW Lasertechnik GmbH

Phone: (0 80 36) 9 08 20- 0

Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

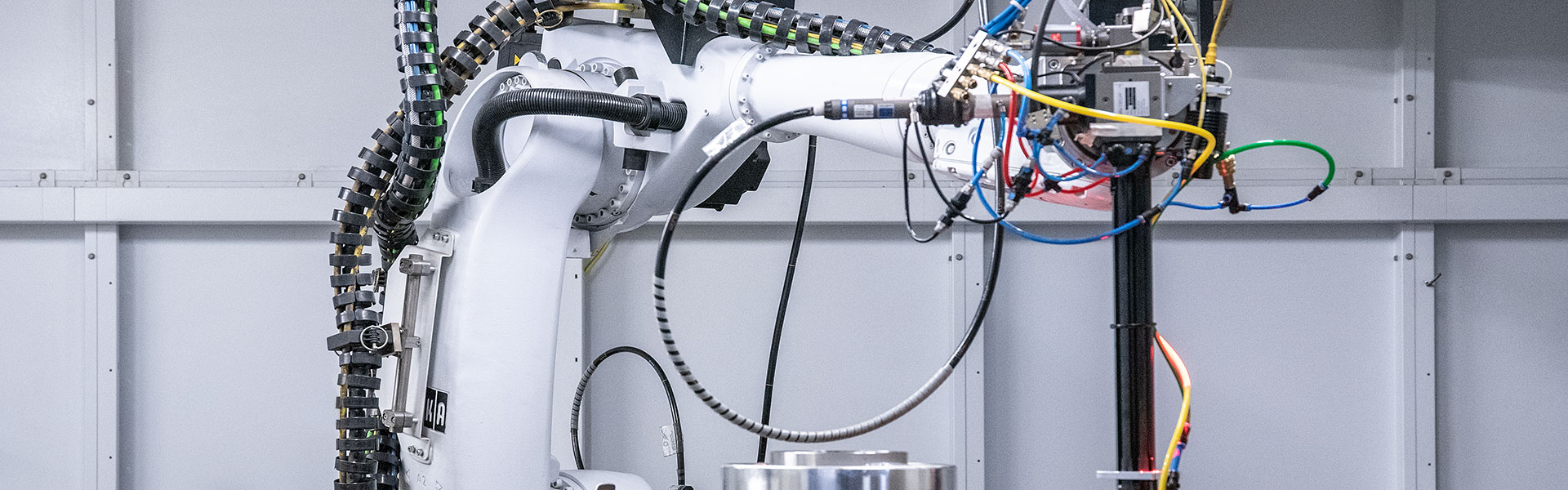

Since 1997, we at BBW Lasertechnik have used laser technology and processes such as laser beam machining, laser welding and more to produce high-precision technical parts for sectors including the automotive, electronics, air-conditioning and energy, and aerospace industries, as well as machine and systems engineering. Have a look at our wide range of services and don’t hesitate to contact us – we will be happy to help!