Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

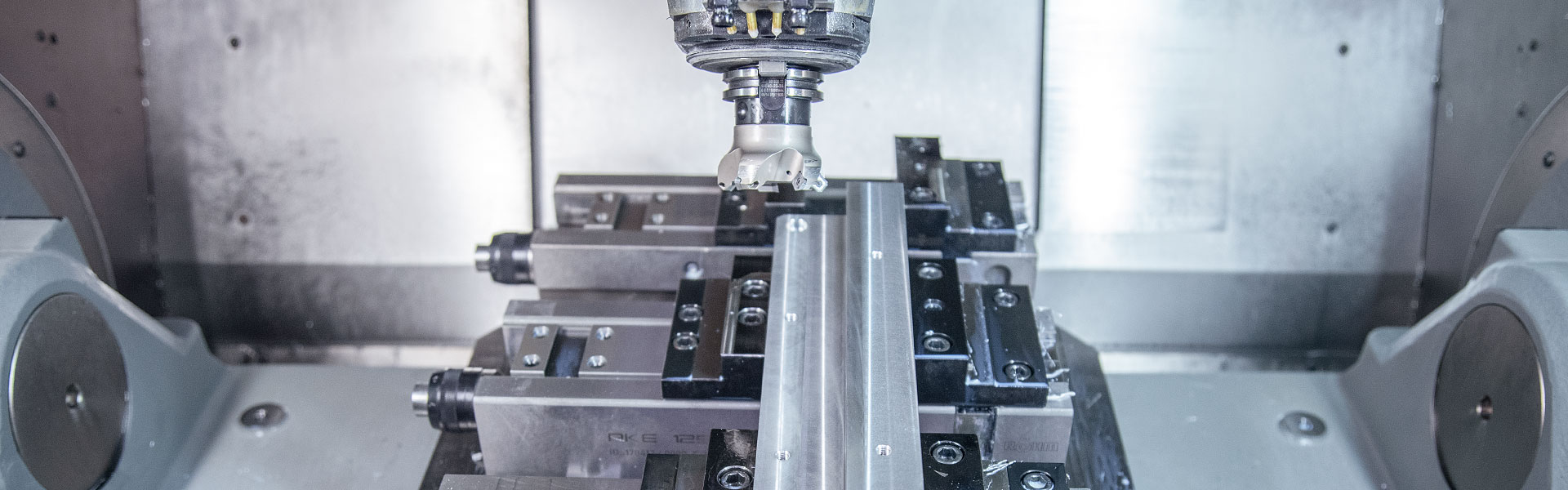

In addition to laser material processing, we also offer customers mechanical manufacturing including post-processing of parts or the production of additional individual parts to create complete assemblies.

Because laser-welded assemblies often consist of more than just individual metal components, we have a dedicated department for mechanical processing. This department uses machining processes, for example milling and turning, to produce components for various assemblies.

Sometimes, components must be manually machined after laser material processing is complete. In this case, we also turn to our mechanical processing team. Plus, we manufacture individual components for fixture and mechanical engineering uses.

We count on a variety of partners for jobs that we cannot completely handle with our own machines. Customers benefit from our trusted, reliable collaborations with our partners and suppliers.