Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

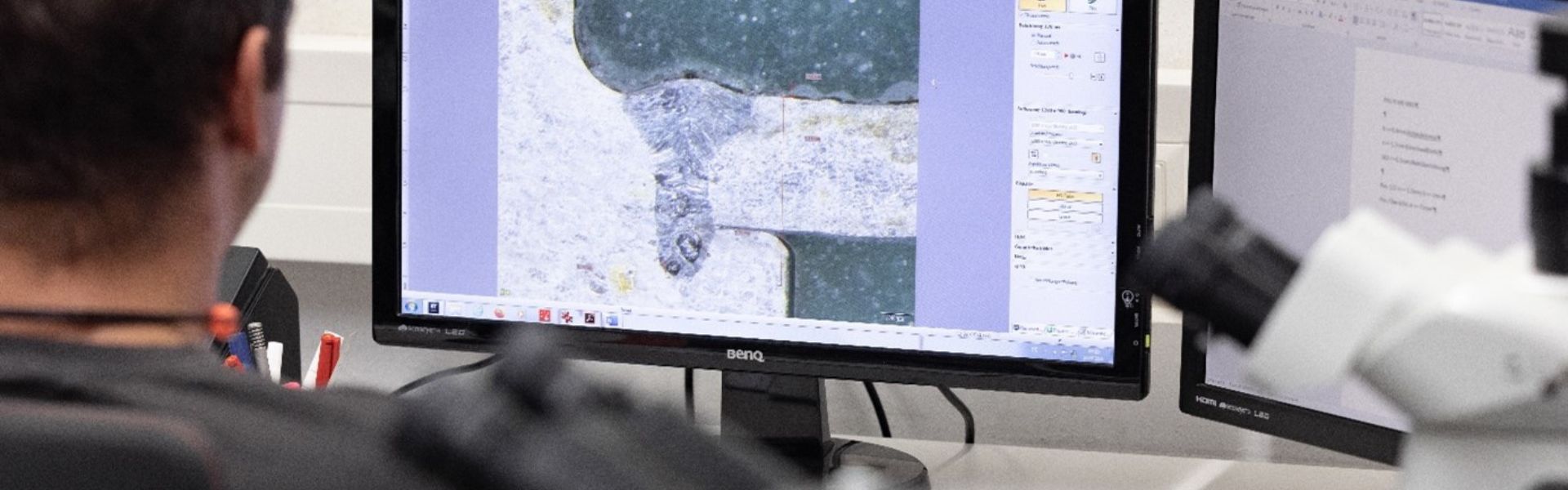

BBW Lasertechnik uses its own metallography and testing laboratory to check the extensive quality requirements for the weld seams of our customers' products.

Numerous tests with metallographic examinations are necessary during the development phase, especially for sophisticated assemblies with high quality requirements for the weld seam, in order to comply with all the necessary quality characteristics. This includes in particular the production of plane, longitudinal and cross sections to analyze the microstructure and weld seam geometry. Thanks to internal processing, our customers benefit above all from rapid implementation through to the finished metallography report. However, the subsequent interpretation of the results and the associated conclusions for our welding process are at least as important. Here we can advise and support our customers with process specialists and unique know-how from over 25 years of experience in the field of laser material processing.

Another method we use is hardness testing, with which we can make statements about the weldability of different materials. A microscopically small indentation is made in the material using a defined indenter. The size or depth of the indentation and the force applied to it provide information about the hardness of the test point. In this way, the weld metal, the heat-affected zone or the base material can be tested. We use this method in particular to qualify our welding processes.

In addition to conventional destructive testing, we also offer our customers non-destructive testing. BBW Lasertechnik has certified inspection personnel in the field of visual inspection in accordance with DIN EN ISO 9712. This is one of the most important inspection methods, as many quality defects in a weld seam are already visible on the surface. Compared to conventional welding processes, the weld seams in laser welding are extremely small. In order to carry out a reliable quality check, the visual inspectors use aids such as magnifying glasses, digital microscopes or endoscopes. Thanks to this fast and cost-effective process, the inspection is not only ideal after welding, but also beforehand or as an interim check.

In order to detect even the smallest, visually invisible cracks on the surface, we offer our customers dye penetrant testing. Using a penetrant and a suitable developer, these small irregularities can be made visible to the eye without destroying the product.

To check for defects within a material, we offer our customers magnetic particle, X-ray or ultrasonic testing.

VT2 testers certified according to DIN EN ISO 9712

(Certified personnel through training courses)