BBW Lasertechnik GmbH

Phone: (0 80 36) 9 08 20- 0

Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

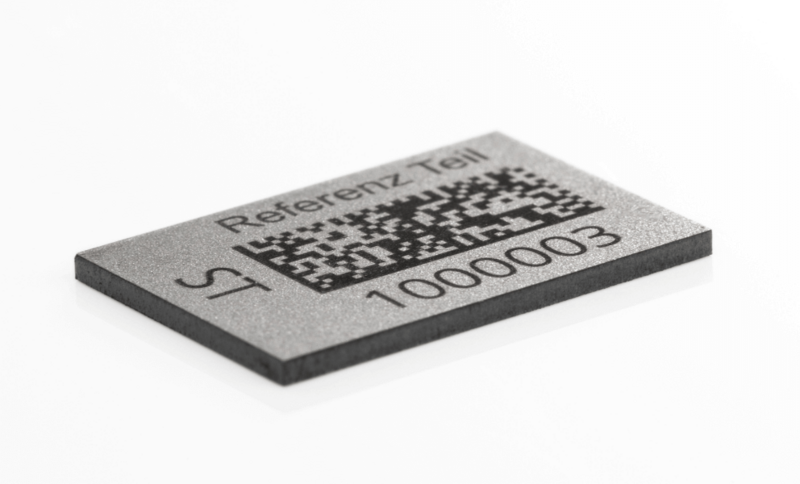

Laser marking is in great demand for the traceability of series production or simply for an individual touch. Here, too, laser pulses are used to change a flat material surface in such a way that a colour change or material removal occurs. The contrast of the marking can vary depending on the pulse energy applied.

With the right choice of parameters, we can create extremely high-contrast and dark markings on a material surface without removing any material. In this process, ultra-short laser pulses are used to create structures in the nanometre range that act like a light trap for incident light. The result is a deep black and corrosion-resistant marking, even on materials such as aluminium.