Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

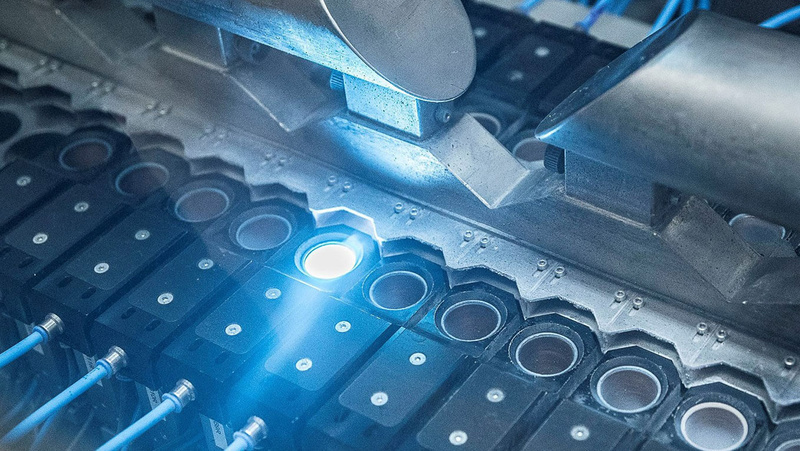

Scanner technology has been successfully used in laser welding for the past 10 years. Compared to conventional fixed optics, scanner welding features two overriding advantages. First, it is possible to achieve significantly higher speed, acceleration and path accuracies in the movement of the laser beam relative to the workpiece – including where there are complex geometries with small radii. And secondly, the scanner can also realize so-called wobble movements whilst the laser beam is moving, which can also have a positive effect on weld seam quality. The high local velocity ensures a stable capillary.

Combining scanner welding with a laser source of high beam quality – i.e. a small focal diameter – increases the flexibility of the weld seam geometry. The main goal when using a scanner and wobbling is to positively affect the currents in the weld pool.

Scanner welding is particularly exciting for the e-mobility, electronics and aerospace industries. This method boasts especially high technical advantages for aluminium and copper. But regardless of the industry, scanner welding is always profitable when speed is required for large quantities.