What is special about the standard?

The standard places particularly high demands on supervising and executing personnel, as well as on operating equipment and production documents - the reason for this is the correspondingly high quality standards for defense technology products.

For example, it must be ensured that a qualified welding supervisor (welding engineer) with comprehensive technical knowledge - recognized by the German Welding Society (DVS) - is always available. In addition, welding work may only be carried out by operators with valid system-related operator qualifications (in accordance with DIN EN ISO 14732).

The suitability of production equipment must be verified by means of process tests, component-related tests or tests during production.

Furthermore, all welding work must be carried out in accordance with the relevant work instructions and process sheets.

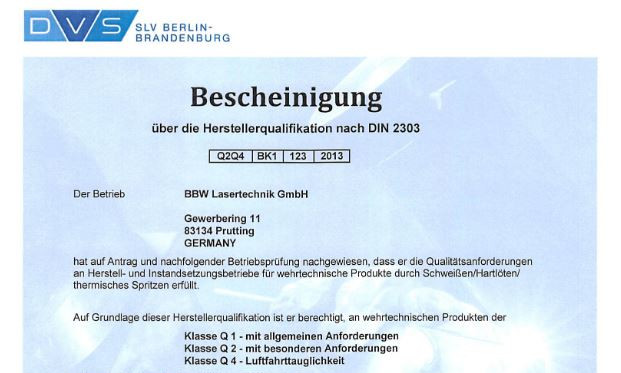

The prerequisite for approval in accordance with DIN 2303 is the successful completion of a company inspection and site inspection, as well as a technical discussion with the welding supervisor.

Manufacturer qualification at BBW Lasertechnik

We have a manufacturer qualification for the process "521 solid-state laser beam welding" for high-alloy steels, aluminum materials and titanium for flying and non-flying components (classes Q1, Q2 and Q4) of the highest safety class (BK1).