As an experienced partner in laser material processing, BBW Lasertechnik offers comprehensive services in the field of stainless steel laser welding. Our skilled team supports you in meeting technical requirements – using state-of-the-art equipment, reliable process control, and in-depth material expertise. The result: durable weld joints that are efficient, precise, and suitable for a wide range of industrial applications.

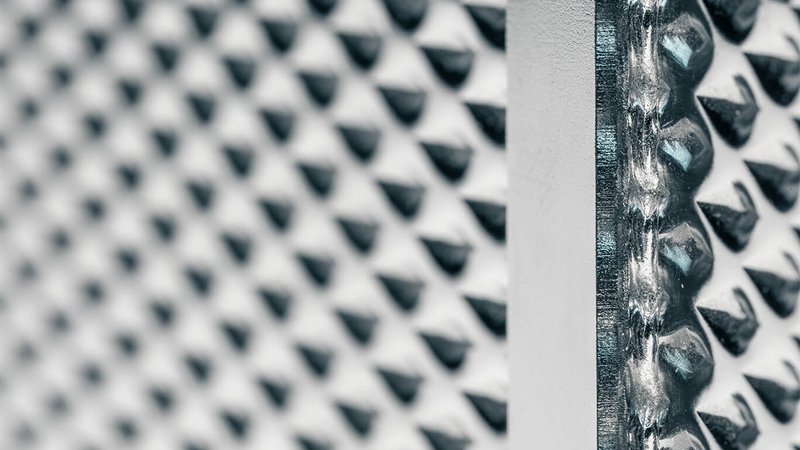

Stainless steel laser welding involves joining components using a focused laser beam with pinpoint accuracy. The laser’s high energy density enables localized melting of the material, allowing for precise joining exactly where needed. The process does not require additional tools and produces narrow, clean weld seams with minimal heat input.

Thanks to its weldability and material properties, stainless steel is particularly well-suited for laser welding. Users also benefit from the high corrosion resistance and mechanical strength of the finished components.

Stainless steel is an extremely versatile material. Laser-welded stainless steel components are commonly used in the following areas:

Sterile, high-precision components that must be reliably joined. Commonly used in surgical equipment and in direct contact with patients.

Components for systems with the highest hygiene requirements, featuring hermetically sealed weld seams.

Components that come into direct contact with food products or aggressive cleaning chemicals – often made from V4A stainless steel (AISI 316L).

Durable welding solutions for mechanically stressed parts. Frequently includes the joining of turned or milled parts with sheet metal components.

For applications with stringent sealing requirements and high demands on electromagnetic compatibility (EMC).

Ideal for use in marine environments or chemical plants with frequent exposure to acids or alkalis.

Not all stainless steels behave the same during welding. Depending on the alloy composition, different requirements arise for the laser welding process. Based on our experience, it is especially important to define the appropriate welding parameters in advance for each material combination and application.

Although stainless steel is generally well-suited for welding, it presents specific challenges—especially when working with high-alloy variants. Common issues include:

At BBW Lasertechnik, we address these challenges through deep expertise in laser material processing and continuous process monitoring – ensuring reliable and high-quality welding results.

When properly executed, laser welding of stainless steel offers numerous benefits:

BBW Lasertechnik offers a broad range of services for stainless steel laser welding – from individual components to full-scale series production. Our customers benefit from a structured approach and close collaboration throughout all project phases.

Our Services:

We also realize mixed-material welds, such as with nickel-based alloys, depending on the specific application. As part of the journey toward serial production, we support our customers with laser-friendly design consulting for optimal component geometry.

At BBW Lasertechnik, we work with high-performance laser sources and advanced welding optics. This allows us to reliably process a wide range of stainless steel alloys – from ferritic grades to austenitic steels.

Our welding strategies are tailored to the specific needs of each customer. Combined with our experience in processing demanding materials, this ensures stable and repeatable results even with tight part tolerances and varying geometries.

The combination of cutting-edge technology, deep expertise, and a strong focus on quality makes BBW Lasertechnik a reliable and specialized partner for projects with challenging requirements.

Over the course of numerous customer projects, we have successfully developed laser welding solutions for stainless steel components – ranging from small series to fully automated high-volume production.

Selected application examples include:

Our solutions are proven in practice, application-focused, and technically sound – even under complex requirements and tight project timelines.