Titanium is distinguished by its exceptionally high specific strength and hardness, combined with low weight and outstanding corrosion resistance—properties that make it particularly suitable for applications in aerospace, medical technology, and motorsports. Laser welding of titanium results in strong and durable joints that are both lightweight and dimensionally precise.

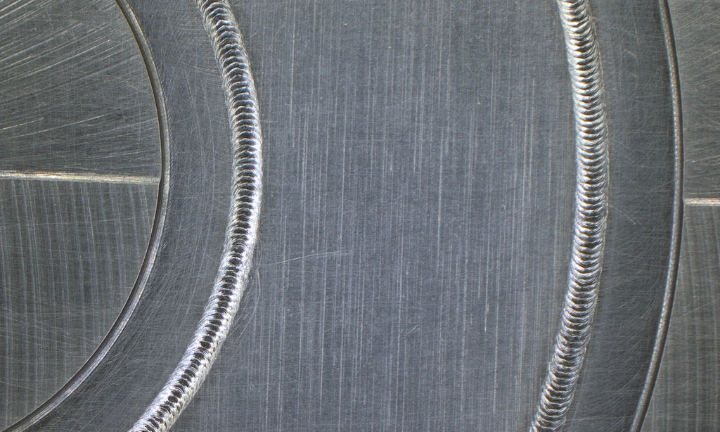

In titanium laser welding, a focused laser beam is used to deliver energy with pinpoint accuracy, creating narrow and clean seams. The laser welding process we employ is suitable not only for thin titanium sheets and delicate joining areas but also enables the welding of larger and deeper seams.

Titanium laser welding offers significant technical benefits, including:

Titanium reacts strongly with oxygen, nitrogen, and hydrogen, which can cause embrittlement at the weld seam. For this reason, an absolutely clean, oxide-free surface and a carefully controlled shielding gas atmosphere are essential.

In addition, titanium’s high thermal expansion and the resulting shrinkage can lead to stresses, making precise process control in laser welding indispensable.

At BBW Lasertechnik, we meet these challenges with a well-structured approach: we ensure meticulous component preparation, consistent shielding gas coverage, and stable process parameters—guaranteeing reproducible weld quality.

As with laser welding of other materials, we offer you a complete service package for titanium laser welding—from development through to series production:

For titanium laser welding, BBW Lasertechnik offers specialized capabilities:

Our solutions are used in industries where titanium is indispensable due to its material properties:

Aerospace – lightweight and dimensionally precise titanium components with stringent quality requirements

Medical technology – implants, surgical instruments, and precision-engineered assemblies

Motorsports – components for high-performance vehicles and e-mobility