Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

The following blog post provides an insight into an internal field study in which we investigated the laser beam welding of aluminum alloys and the influence of power distribution on weld seam quality. The results of the study were presented at LANE 2020.

Laser welding of aluminum for structural and electrical parts is becoming increasingly important in many industrial sectors, especially in the electromobility sector. A variety of aluminum alloys exist for different requirement profiles, but their weldability can be challenging. Typical weld seam irregularities that can occur are hot cracks and pore formation. These can lead to a deterioration in quality or even a loss of functionality. Various countermeasures exist to prevent or minimize welding defects. Some of these irregularities have already been addressed in the last blog post.

At BBW Lasertechnik, we strive to continuously improve our process reliability and quality of results. To achieve this, we are constantly evolving: on the one hand, by applying our specially developed process strategies and, on the other, through a research and development department that gains its own insights and in turn makes them available to the research community.

In the following, we present the results of an internal field study, which was also published at the LANE 2020 symposium. The starting point is the formation of high porosity within the weld seam of certain aluminum alloys, which should be avoided. We have already examined the formation mechanism of pores in more detail in the first blog post (rupture of part of the vapor capillary and inclusion of the gas bubble in the solidified melt). Different strategies can be used to reduce the formation of pores. One well-known approach is the use of a so-called double-focus technique: during the welding process, not just one laser beam is focused on the joint, but two spots in succession. This makes it possible to expand and stabilize the vapour capillary, which reduces the probability of capillary collapse or breakage. However, this can only be implemented without restrictions with 3D-capable welding heads, as the spots have to be realigned accordingly when the direction is changed.

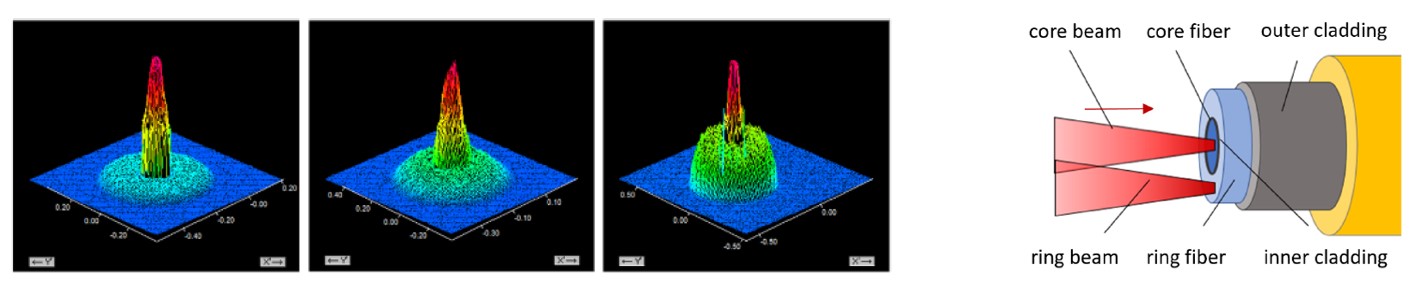

Another approach is the use of concentrically overlapping beam spots, realized by a so-called 2-in-1 fiber. Here, the laser radiation is guided through an inner and outer fiber at the same time, whereby the power proportion per fiber can be controlled via the power control. This technology is offered by various laser manufacturers, e.g. as Brightline (Trumpf), AMB (IPG), ARM (Coherent) or Corona (Nlight).

In the test setup, we investigated whether a variation of the power distribution between the inner fiber core and the outer fiber ring can reduce the porosity in the weld seam. We used a Trumpf disk laser with a Brightline module, which is implemented using a 2-in-1 fiber. The fibers have a diameter of 75 µm (inside) and 300 µm (outside), resulting in a focal diameter of the laser spot in a ratio of 1:4. The welding speed of 2 m/min was deliberately chosen to be slow. Although this is counterproductive for pore avoidance - slow welding tends to cause more and larger pores - it allows changes in the relative porosity to be seen particularly clearly by varying other parameters.

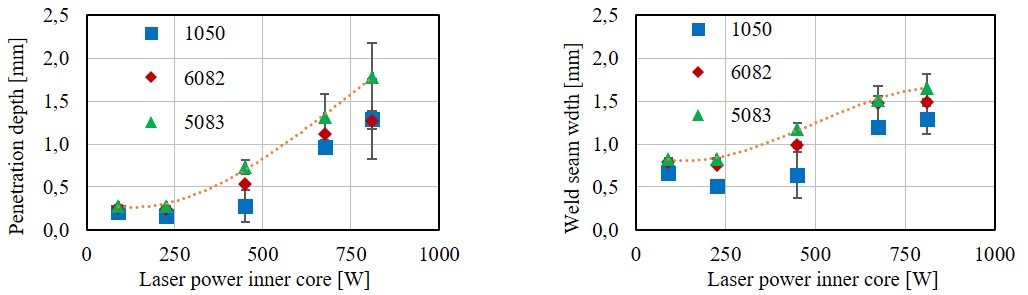

In the following, we left the total power unchanged, but increased the relative power of the inner fiber (and simultaneously reduced the relative power of the outer fiber). Pure aluminium (AW 1050) and the two aluminium alloys AW 6082 and 5083 were examined. Figure 2 on the left shows that the welding depth increases with a greater proportion of power in the inner fibre. At the same time, the seam width increases (Figure 2, right), but reaches saturation with a higher proportion of power in the inner fiber.

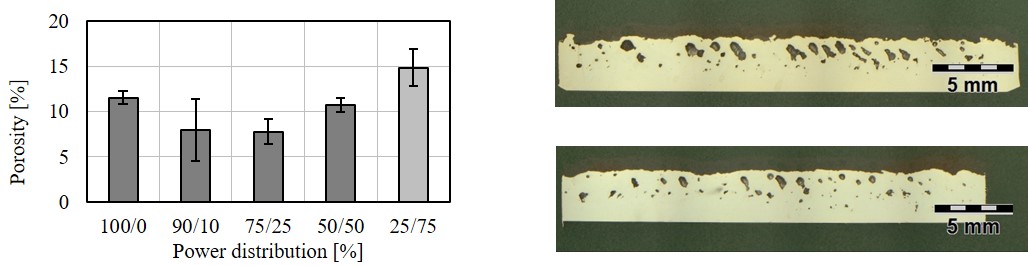

In the next step, we look at the porosity under variation of the relative power components, here as an example for the pore-prone aluminum alloy AW 5083. In this regard, a micrograph of the weld seam was made for each parameter set and the relative porosity was determined (Figure 3). It can be seen that the relative porosity with the standard setting (100% power content in the inner fiber core) is approximately 12% (Figure 3, top right), but can be reduced to 8% with slightly reduced power in the fiber core (Figure 3, bottom right). If the weld seam is classified according to the DIN ISO 13919-2 standard, which applies to aluminum alloys, this would mean an improvement from "unacceptable" to evaluation class D (<10%, low quality). Although the technology of a 2-in-1 fiber cannot ultimately completely prevent porosity in a weld seam, it can significantly reduce it. Another option that leads to a reduction in porosity is high-speed welding. We will shed more light on this and what other technologies are available in one of our following blog posts.

The results of this field study are an excerpt from the article "Influence of power distribution on weld seam quality and geometry in laser beam welding of aluminum alloys" (https://doi.org/10.1016/j.procir.2020.09.086) published in Procedia CIRP and were also presented at LANE 2020.

A contribution by Eric Punzel

Sources:

Figure 1: Haug, P., Weidgang, S., Seebach, J., Speker, N., Hesse, T., Bisch, S.. Beam Shaping BrightLine Weld - Latest Application Results. Lasers in Manufacturing Conference 2019 (LiM 2019).

Figure 2 and 3: Punzel, E., Hugger, F., Dinkelbach, T., Bürger, A. (2020). 11th CIRP Conference on Photonic Technologies [LANE 2020] on September 7-10, 2020: Influence of power distribution on weld seam quality and geometry in laser beam welding of aluminum alloys. Procedia CIRP, 94. available at: https://doi.org/10.1016/j.procir.2020.09.086.