Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

In the following article, we look at the theory of lasers - from the definition of the term and the beginnings of lasers to the different types of lasers, their structure and the individual areas of application.

What is a laser? The term "laser" stands for "Light Amplification by Stimulated Emission of Radiation" and translates as "light amplification by stimulated emission of radiation". A laser is therefore nothing more than light with an extremely high power density.

The origin of light

General light usually emanates from a source. This can be a glowing natural solid such as the sun, a hot gas or an artificially produced light bulb. The creation of light is a process in the atom. Bohr's atomic model explains the movement of electrons in radiation-free orbits, which means constant kinetic and potential energy relative to the atomic nucleus. These orbits are firmly defined and subject to clear rules, the so-called quantum numbers. If an electron changes orbit, this happens in conjunction with energy absorption or energy release. The electrons are therefore first "excited" by the supply of energy, i.e. brought to a higher energy level. As this state is not stable, the excited electron falls back to its original state after a short time. The previously received energy is released in the form of electromagnetic radiation.

The atom is constantly exchanging energy with other atoms in its environment. This process is repeated again and again and leads to the emission of radiation of different frequencies or wavelengths (incoherence). If the radiation is in the range of visible light, the body can be seen to glow. This process is also known as spontaneous emission. The resulting radiation or photons are non-directional and have no relationship to each other.

Like light in general, laser light is generated during a precisely defined transition of an atom from a higher to a lower energy state. In order to generate the laser beam continuously, it is necessary to supply energy from outside. This can be done in different ways: In the case of gas lasers, through electrical current pulses, in that the molecules leave the resting state and begin to rotate or oscillate. In the case of solid-state lasers, usually through intensive optical irradiation, which causes electrons to transition to a higher energy level.

On returning to the ground state, the energy is released again as electromagnetic radiation. If this elementary radiation hits a particle that is still excited, the return to the ground state is also forced here, and so it goes on. One elementary radiation has now become two. This is also referred to as stimulated emission. All radiations have a uniform direction and relationship to each other and the radiation is amplified. This results in the following important properties of laser light:

Laser light can be extremely strongly focused due to the two points mentioned, which means that extremely high power intensities can also be achieved.

In order to amplify the radiation through stimulated emission, more particles must be in the excited state than in the ground state. However, the excitation state must be extended in time, as in most materials an energetic decay occurs within microseconds. For this reason, only so-called metastable materials, which enable holding times that are several orders of magnitude longer, can be considered.

In order to find more excited than unexcited elementary particles, the laser material must be put into a high energy state. As a rule, a 4-level laser system is used for this. The material is first put into a high, rapidly discharging energy state, while the level below is metastable. Due to the rapid discharge, there are consequently more excited than unexcited particles in the energy level below. The laser emergence process ultimately takes place between the 2nd and 3rd energy level.

The history of the laser

1917: Albert Einstein formulates his theory of stimulated emission.

1951: Charles Towns builds a device that generates radiation based on the principle of stimulated emission - however, this involves microwaves and not light; the device is called a maser.

1959: PhD student Gordon Gould describes the construction of an optical resonator to generate laser light and is the first to use the term laser.

1960: Theodore Maiman builds the first laser based on a solid-state ruby resonator that emits red light. Ruby lasers are used in ophthalmology shortly afterwards.

1962: The first semiconductor laser is developed, but it is not until ten years later that this laser variant conquers the mass market as a data reader for CDs.

1964: The first CO2 laser is developed, but only has an output of one milliwatt. Four years later, however, outputs in the kilowatt range are already possible. In the following years, this gas laser establishes laser material processing, mainly laser cutting and welding. The design of a CO2 gas laser dominated industrial production for many years and was only replaced by the solid-state laser at the beginning of the 21st century.

1980s: The fiber optic cable is developed as a new data transmission method.

1990s: The CO2 laser is slowly, then steadily, pushed out of the market by solid-state lasers. Initially, the energy efficiency of solid-state lasers was significantly worse than that of gas lasers, but their use was still justified due to their better focusability. With the advent of the first disk and fiber lasers, however, energy efficiency was clearly in favor of solid-state lasers. From the 21st century onwards, these lasers were also able to penetrate the kilowatt range in terms of output power.

From 2010: Ultra-short pulse laser technology (USP) becomes established in the industry. Laser pulses in the pico- to femtosecond range enable so-called "cold ablation", as the material is vaporized directly and no molten material is produced.

2010: Laser-induced nuclear fusion is tested in the USA in the search for renewable energies.

Laser types and their properties

Today, there are various types of lasers for material processing, each with different properties. Lasers are generally classified according to the laser medium.

Solid-state lasers - The laser-active medium here is a doped crystal rod or a semiconductor. The excitation takes place optically through flash lamps, arc lamps or laser diodes, or electrically in the case of a semiconductor laser. Typical examples are

Gas laser - A gas mixture flows through the resonator, the "pumping" takes place through electrical gas discharges in the mixture.

Dye laser - A fluorescent dye is used here as the laser-active medium. The special feature of this type of laser is its tunability to different wavelengths. Dye lasers are rarely used today and have been replaced by other tunable variants, such as titanium-sapphire diode lasers.

What are the components of a laser?

A laser system basically consists of a resonator, beam guidance and beam focusing. The system component for generating laser radiation is known as the resonator, while the core module is always the laser-active medium. Both can be constructed differently depending on the laser type. Some examples of laser type resonators are listed below.

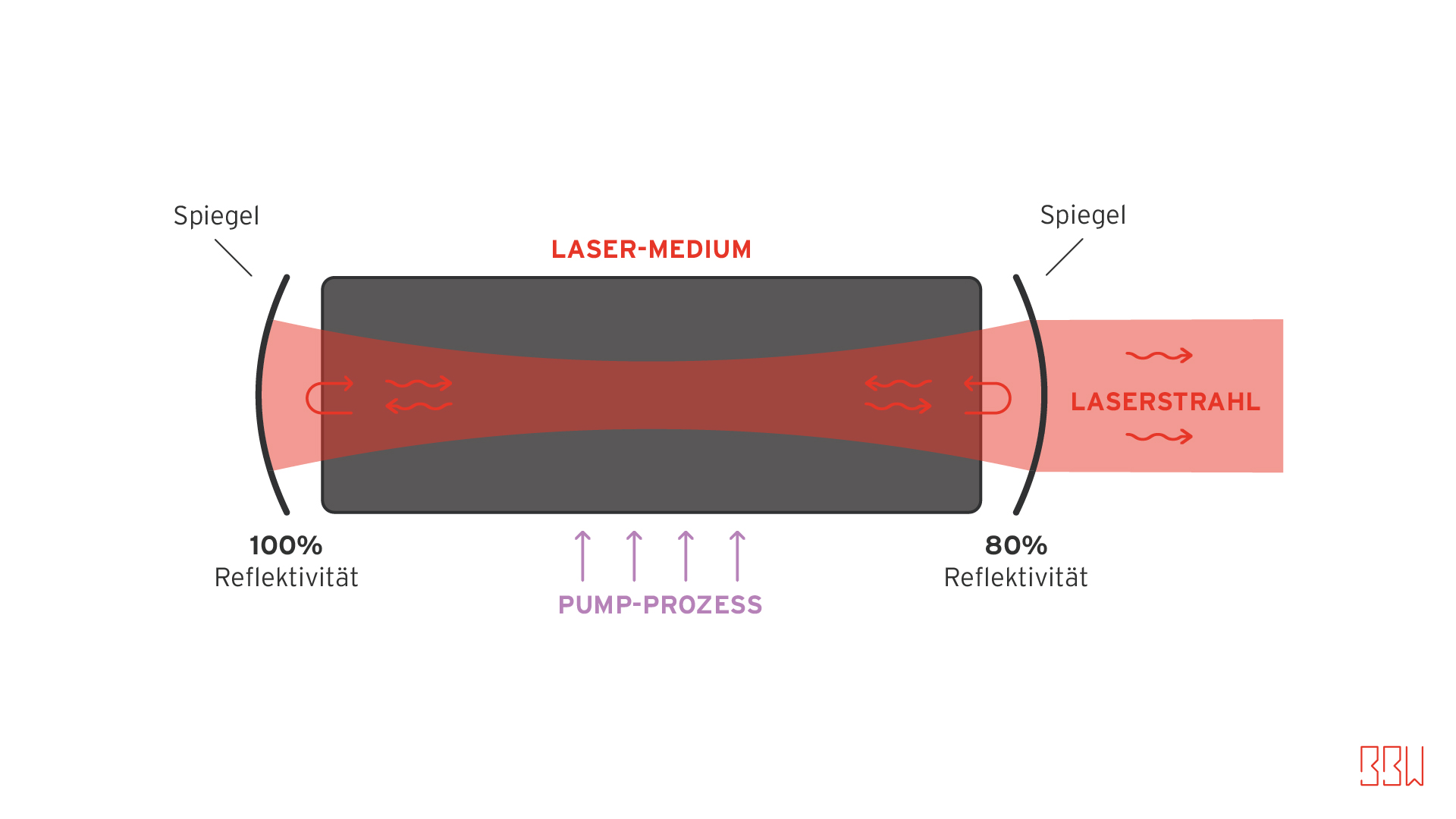

Classic structure of a solid-state resonator

By supplying external energy, optical energy is "pumped" into the medium and energetic excitation takes place. Usually, for example, gas discharge lamps (classic, old lasers) or laser diodes are arranged around the laser medium.

In the example of the Nd:YAG laser crystal, the carrier material consists of YAG (yttrium aluminum garnet). Neodymium is doped in and forms the actual laser-active medium.

Laser radiation is generated by stimulated emission, which is reflected back and forth at both mirrors. Only a small proportion can reach the outside via a partially transparent mirror and is available for material processing.

The disadvantage of this system is the cooling of a rod crystal with finite thickness and length - because the center is always hotter than the outer areas. The solution to this problem is either a crystal as a very thin disk (=disk laser) or as a very long fiber (=fiber laser).

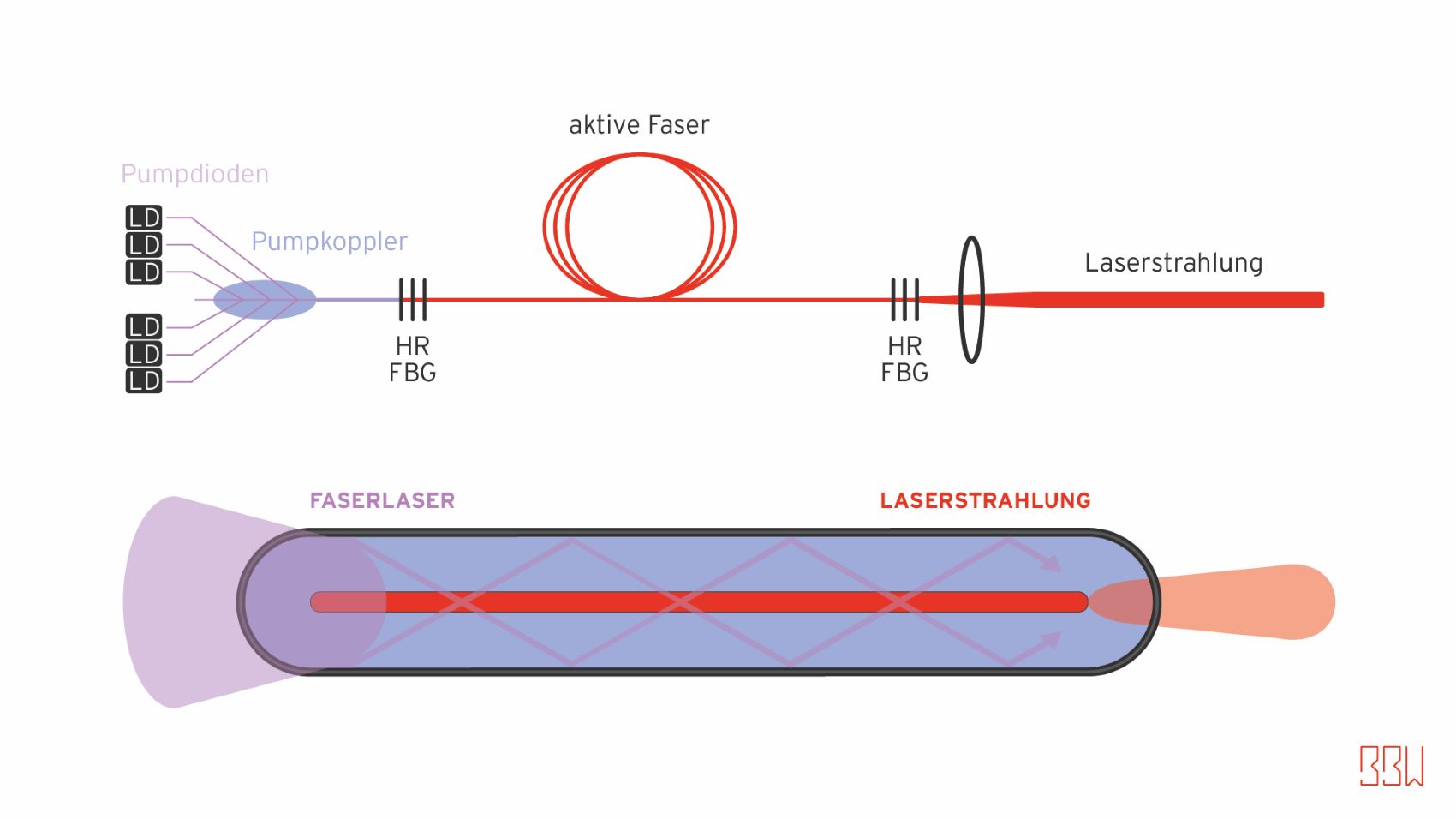

Structure of a fiber laser resonator

In the fiber laser resonator, the fiber itself is the resonator; laser diodes are used to "pump" into the fiber. Classic fibers consist of a core and a cladding: The pump radiation passes through the cladding and core, but is totally reflected at the outer wall of the fiber. The laser radiation generated in the core is totally reflected at the core-cladding interface. In contrast to the classic resonator, there is only one pass through the fiber, no multiple reflection between two mirrors. Thanks to extremely small fibers, incredibly high beam qualities are possible.

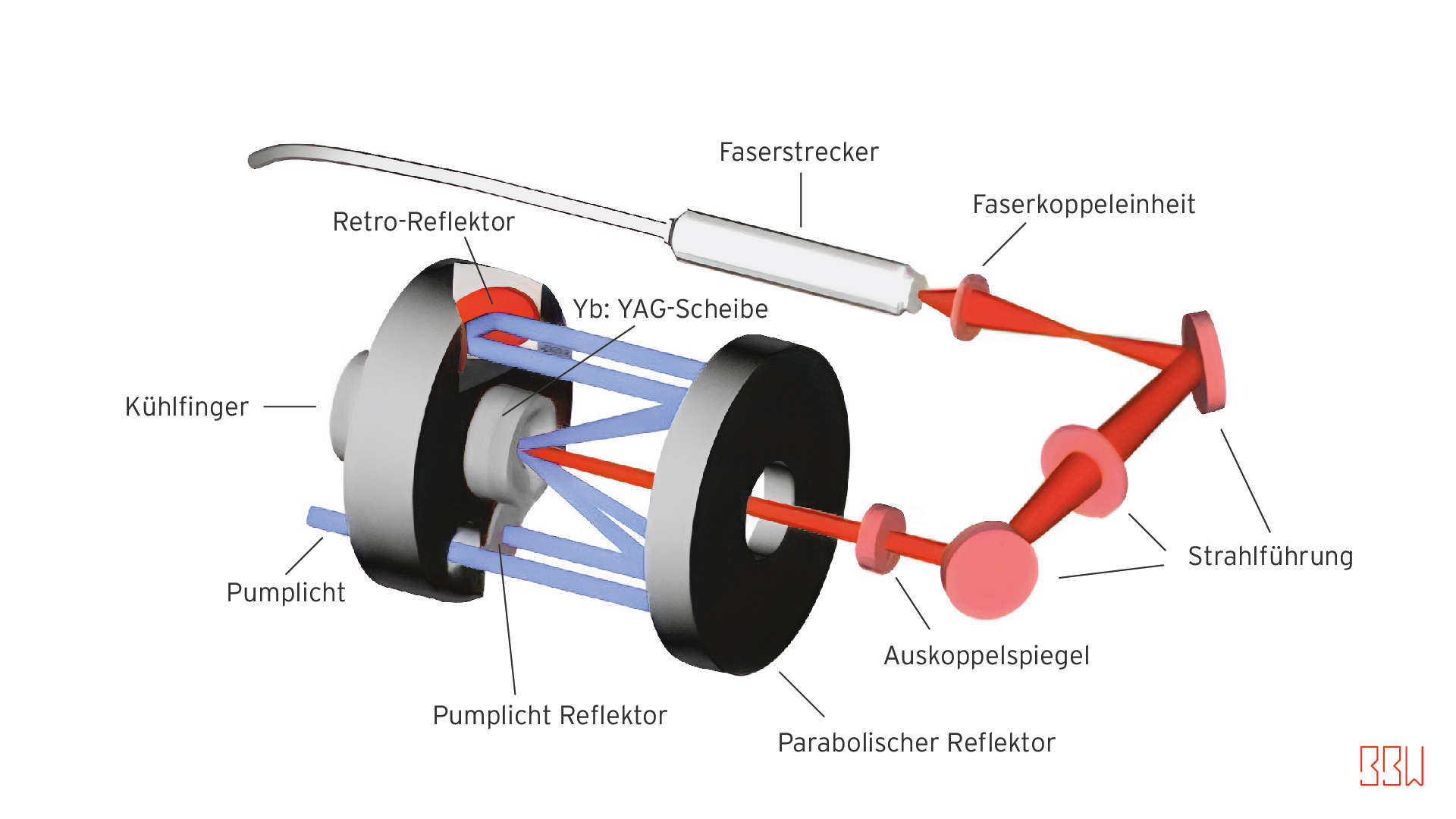

Structure of a disk laser resonator

In a disk laser, the laser-active medium is a very thin disk, the back of which is mirrored and cooled at the same time. A mirror system allows the pump radiation to pass through the disk several times. By combining several disks in a resonator system, very high outputs are possible.

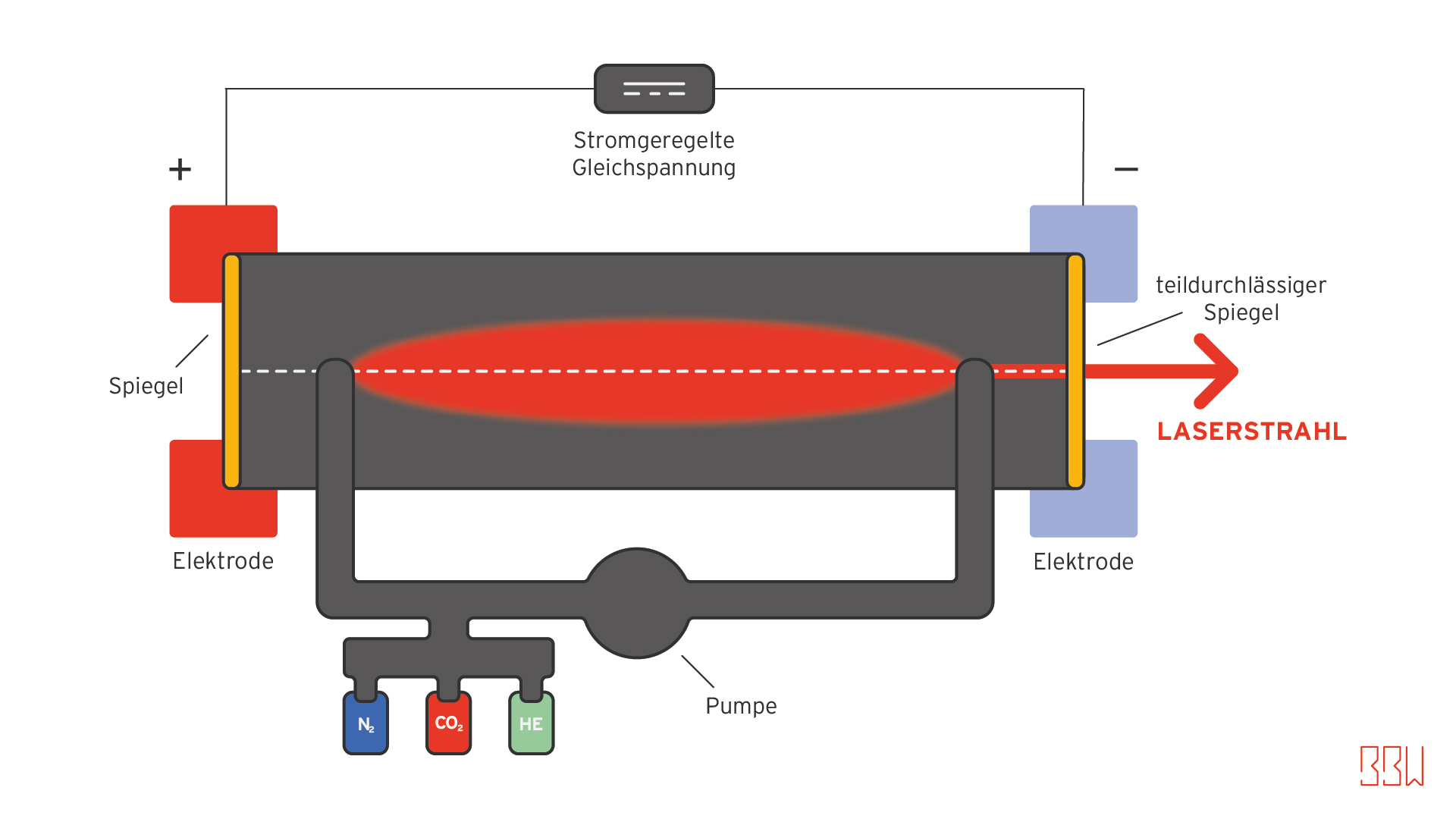

Structure of a gas laser resonator

Similar to a classic solid-state resonator, the laser-active medium is located in the center and any laser radiation generated is reflected back and forth between two mirrors. What is different here, however, is that the laser-active medium is present as a gas mixture. In the example of the CO2 laser, this is a nitrogen-helium-carbon dioxide mixture. The gas components fulfill the functions of pump gas, cooling gas and impact partner for the CO2 molecule cooling and form the active medium. They are excited by electrical discharges. The energy transfer does not take place through the excitation of electrons, but through the excitation of molecules to vibrational states.

Areas of application for lasers

"Laser physics and quantum optics are the foundations of a renaissance in optics. The century that is coming to an end was the century of the electron. I am convinced that the 21st century will be the century of the photon (light). The laser is developing into a universal tool in many areas." (Prof. Dr. Günther Huber, 1999 at the 10th North German Laser Day)

The classic area of application for lasers is laser material processing: laser welding, laser cutting, laser drilling, laser marking, laser sintering and surface treatments such as USP processing, laser hardening and laser polishing.

Other areas of application:

A contribution by Eric Punzel