Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

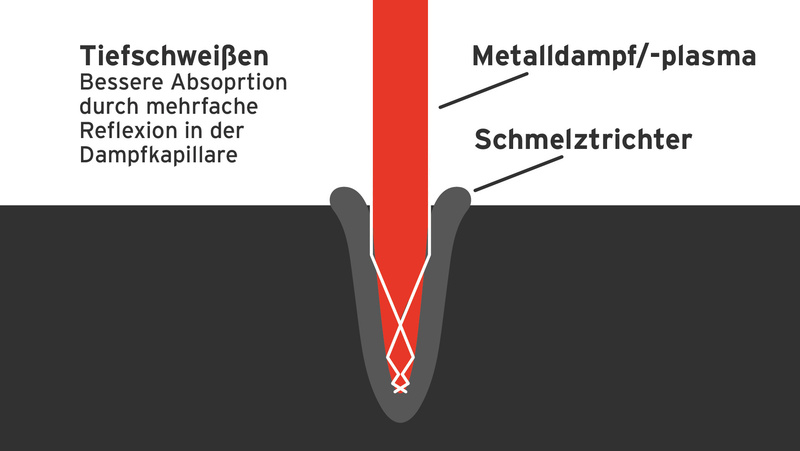

One important requirement for deep penetration welding is high power intensities of around 1 MW/cm². In contrast to heat conduction welding, the laser not only melts the metal, it also vaporises it. This creates a capillary – the so-called keyhole. Within this keyhole, the laser beam can penetrate much deeper into the material.

The weld seams are characterised by their uniform internal structure. The depth of the weld is significantly greater than its width. It is important that a high absorption of laser radiation does not develop in the plasma plume. Additional material may be used for jobs with material compounds, or to bridge gaps. Inductive preheating of the components that are to be welded can increase welding depth whilst keeping the laser power needed the same.

Gas (CO2) or solid-state continuous beam lasers are mostly used for deep-penetration welding.

Deep penetration welding is used, for example, for transmission parts in the automobile and aerospace industries, and in sheet metal processing.