Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

In e-mobility, but also for stationary operation, fuel cells can make an important contribution to global CO2 reduction in the future and in many cases are a sensible alternative and supplement to battery technology. The laser is an important tool in the production of fuel cells and BBW Lasertechnik is therefore the right partner in the development and production of components and assemblies for fuel cells.

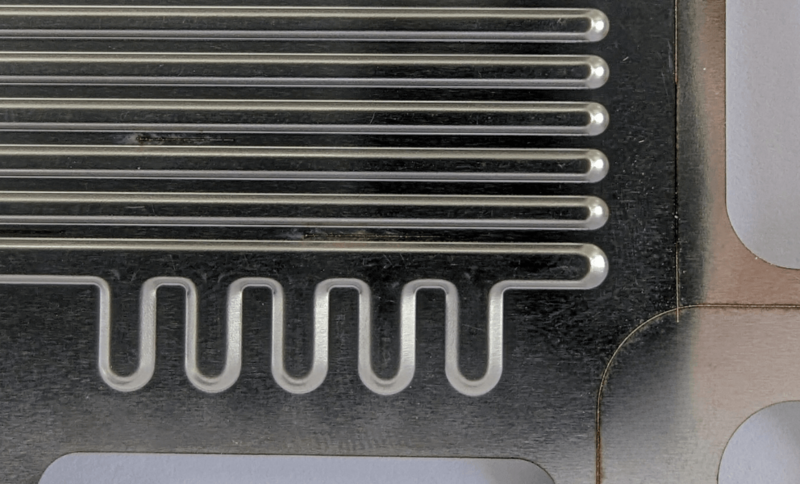

An important component of fuel cells are bipolar plates. BBW Lasertechnik can support you in the production of bipolar plates on an industrial scale. Two important applications of laser material processing for bipolar plates are laser cutting as well as laser welding. In addition, BBW Lasertechnik offers supplementary processing and testing steps, e.g. leak testing, and is thus able to offer assemblies from a single source.

Laser welding meets the requirements for joining bipolar plates. In laser welding of bipolar plates, thin metallic plates with a thickness of about 100 µm or less are welded together. These are usually made of stainless steel or titanium. The weld seams and the welding process must meet stringent requirements: the weld seams must be gas-tight. Furthermore, very large weld lengths are achieved on the individual bipolar plates in order to form the channels for the distribution and conduction of the reaction gases. Since the bipolar plates are also stacked, a large quantity of bipolar plates is also required. In sum, enormous weld lengths follow for the manufacture of a fuel cell. Consequently, the highest processing speeds are required for laser welding. Likewise, the susceptibility of the welding process to defects must be reduced to a minimum in order to keep reject rates low.

Central requirements for laser welding of bipolar plates are summarized below:

At BBW Lasertechnik we use 2D-on-the-fly systems. In these systems, the movement of the axis system and the laser scanner is synchronized with each other, whereby the weld seams of the bipolar plates are realized without repeated coupling and decoupling of the laser beam into the materials, which in turn significantly reduces the susceptibility to errors and thus the reject rates. BBW uses single-mode fiber lasers with 2 kW as beam sources for this purpose.

For quality assurance during laser welding of bipolar plates, BBW Lasertechnik uses OCT technology (optical coherence tomography). This allows the welding depth of the weld seam to be measured during the process and a check of the height profile of the finished weld seam to be carried out. This also ensures that the bipolar plates are securely welded and at the same time not welded through. At BBW Lasertechnik, we can also perform tests to ensure tightness, as needed.

Even the best laser technology only works in conjunction with the right clamping technology. When laser welding bipolar plates, it must therefore be ensured that there is no gap between the individual parts on the surface of the weld seams. For this purpose, we at BBW Lasertechnik use modular clamping concepts for tests and prototypes and can implement product-specific clamping concepts for series processes.

At BBW Lasertechnik, we are constantly researching the latest methods of laser material processing and can thus provide our customers with access to innovative manufacturing technologies. For example, we recently successfully completed a cooperative and international research project to develop an advanced technology platform for laser welding of bipolar plates. We can now make this available to our customers.

After the bipolar plates have been embossed, they must be trimmed to the final contour. Laser cutting is a flexible and contact-free process for this purpose. The use of tools can be dispensed with, which is a great advantage over other processes, especially in development.

BBW Lasertechnik is specialized in laser fine cutting: We achieve precise and burr-free contour cuts on thin sheets and foils. We can reliably position bipolar plates on our systems.

Our services for the production of bipolar plates include the following steps:

We can support you with bipolar plates for fuel cells from initial prototypes to series production.