Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

The welding of dissimilar metal joints refers to the joining of different materials. The joining partners aluminum-copper, aluminum-steel and copper-steel are mostly demanded here. Due to strongly differing material properties, welding is challenging because a complete mixing of both materials leads to intermetallic phases, brittle zones, and cracks. At the same time, a successful joint can be very attractive in the e-mobility sector due to the extremely positive electrical and thermal conductivity properties as well as a potentially high cost saving in material price.

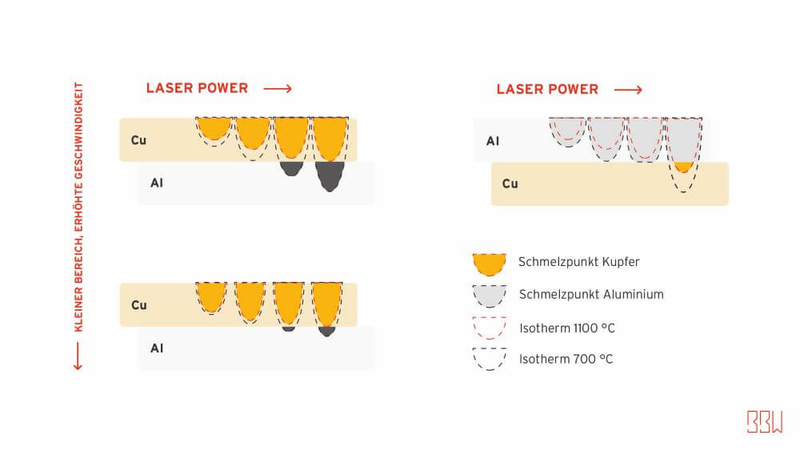

For an aluminum-copper joint, for example, there is a significant difference in terms of melting temperature (aluminum 660°C, copper 1,085°C). In addition, there is a thin aluminum oxide layer on aluminum sheets with a melting temperature of over 2,000°C, which must first be "broken through" by the laser radiation. Depending on which joining partners are on top, different resulting effects may appear: In the case of copper at the top, the sheet is not yet completely melted through, while the lower joining partner is already melting. Conversely, aluminum at the top may already be completely melted, while the lower copper sheet still solidified.

So far, the most promising approach has been shown to be joints with a shallow weld penetration depth, where the materials are mixed together as little as possible. This can best be achieved by lasers with dynamic beam shaping or special intensity distribution.

Copper-steel and copper-aluminum joints are currently in particular demand for power connectors for battery cells.