Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

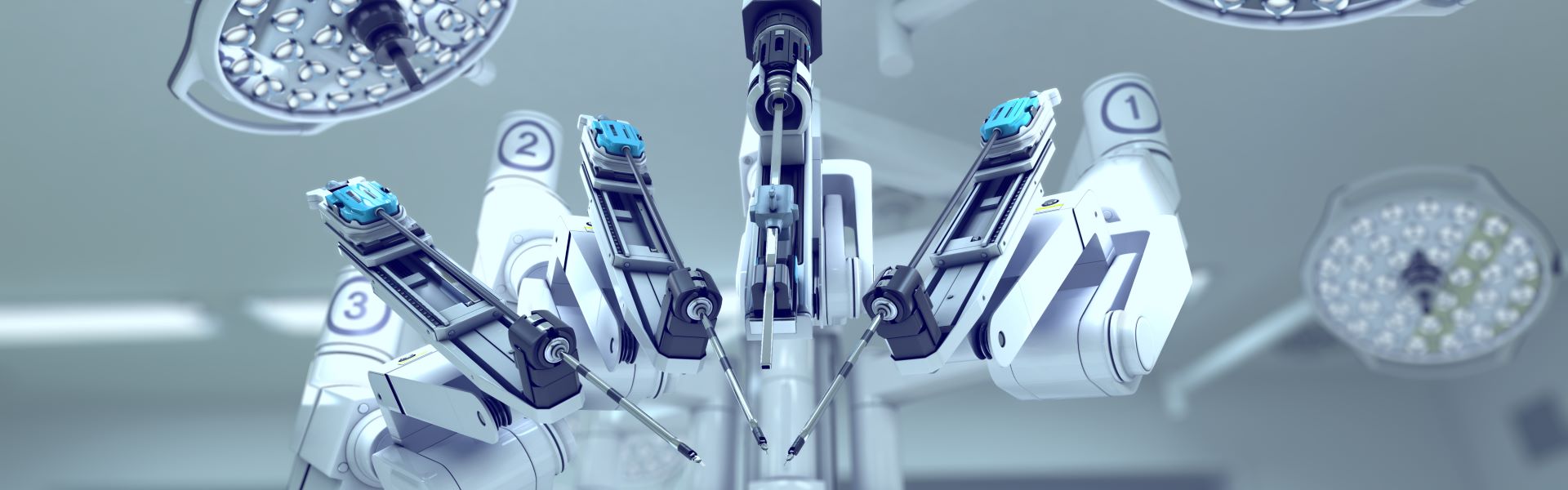

BBW Lasertechnik's first order was for the laser fine cutting of stents. This means that we have been active in medical technology since the beginning of our company's history. This has developed rapidly in recent years, with precision and sterility still playing an essential role.

We use laser tools to weld needles with diameters of 1.25 mm and 0.70 mm for our customers. Hygienic weld seams are our top priority in the production of holders. We also specialize in the production of micro-holes in baffle plates.

BBW Lasertechnik offers customized solutions in the field of laser material processing for the medical industry.

In the production of medical needles, we are able to weld and crimp material with a diameter of 1.25 to 0.70 mm. We are able to weld through one tube without welding through the second tube. The result is particularly fine welding spots.

We offer our customers a wide range of services for the camera angulation: From laser cutting a tube and laser welding to vibratory grinding and manual testing.

A special production feature at BBW Lasertechnik is the achievement of a flexible stainless steel tube by laser cutting. The fine weld seams is characterized by the lowest possible distortion and a high holding force.

We manufacture sheet metal components in-house for the production of heating basins and offer a comprehensive range of services - such as laser cutting, bending, laser welding and pickling.

Each of our products undergoes a 100% leak test. We also pay particular attention to detail: our production processes are optimized to prevent scratches and rough edges. In this way, we guarantee not only perfect functionality but also aesthetics and safety.

For brackets in the medical industry, we offer laser welding of the assemblies provided.

In order to meet the high standards of hygiene, we guarantee a clean and smooth weld seam on which no bacteria can settle.

In the production of arm plates for the medical industry, we offer our customers services ranging from the development of fixture concepts to fine tube machining.

We are able to machine bars smaller than 100 µm, even if the components are not dimensionally stable.

For baffle plates, our service includes micro-drilling with a diameter of Ø 100 µm, laser cleaning and the ability to drill more than 6,000 holes.

A special feature here is the targeted production of "conical" holes with a tolerance of less than 10 µm without any heat distortion. The high standards of the medical industry are achieved.