Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

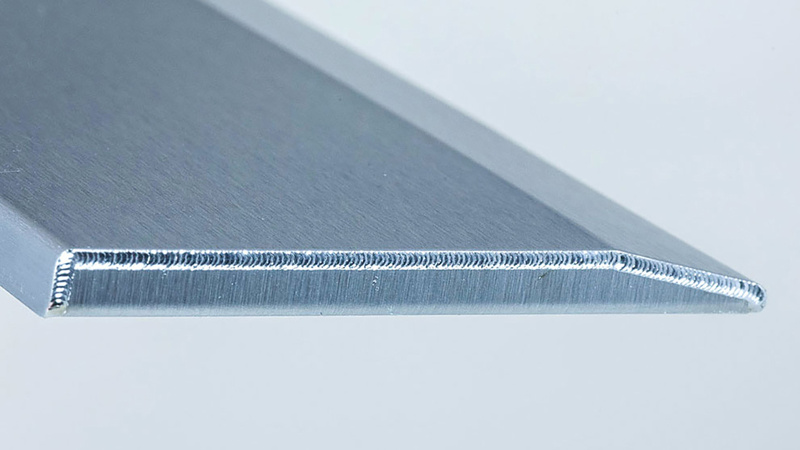

Pulse welding creates a join from consecutive weld beads. The current of the laser is pulsed, allowing the melt to cool during the pauses between pulses. For this reason, there are additional parameters to consider when using pulse welding. The frequency of the pulses results from the length of time between laser pulses, and the length of the individual pulses also plays an important role. An equally important parameter is the current of the individual laser pulses. By “super-elevating” the pulse, the power of the individual laser pulses can be adjusted using the average power of the laser beam source. Here it is also possible to adjust the power within the individual laser pulses via so-called “pulse shaping” in order to improve the quality of weld seams.

Pulse welding is often used when the energy input from welding needs to be kept as low as possible.

Continuous wave (also known as “cw”) welding uses continuous laser beams. This process is a prerequisite for deep penetration welding – however, heat conduction welding is also possible using continuous waves. Continuous wave welding only became widespread with the rise of high-power CO2 lasers. Today, fibre or disk lasers are considered state-of-the-art.