Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

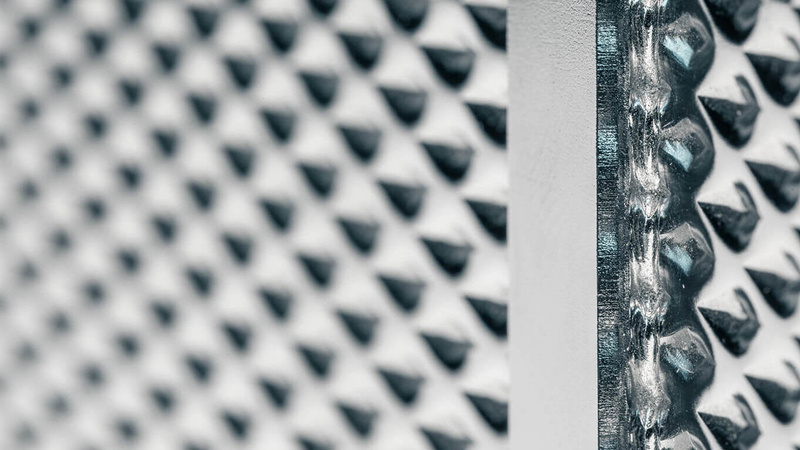

Because stainless steel has mostly a good weldability and is commonly used in many products across many industries, laser welding of stainless steel is a standard procedure. Stainless steel is affordable, corrosion resistant and good to work with. Plus, it often takes over purely mechanical functions. However, laser welding can become more challenging with higher-alloy steels that have a higher resistance to corrosion. One thing to note about stainless steel is that it cannot necessarily be rapidly welded due to its propensity to undercuts and humping effects. Molten stainless steel is more viscous and therefore less fluid than other materials. From a purely metallurgical stance, the materials can be welded uncritically if they solidify ferritically. In contrast, stainless steel with a higher nickel content tends to solidify austenitically, making it prone to cracking if contamination comes from upstream processes. The cleanliness of the components is therefore critical when laser welding.

When stainless steel is welded using pulsed laser beams, it offers advantages in terms of the heat applied and the associated potential distortion. However, fast solidification can also lead to cracks. The susceptibility to cracking can be reduced with the help of continuous laser beams.

Stainless steel is used in many industries and to make a wide variety of products, making the potential applications for laser welding practically limitless. Stainless steel is used, for instance, in mechanical engineering, electronics and the pharmaceutical and biotech industries.