Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

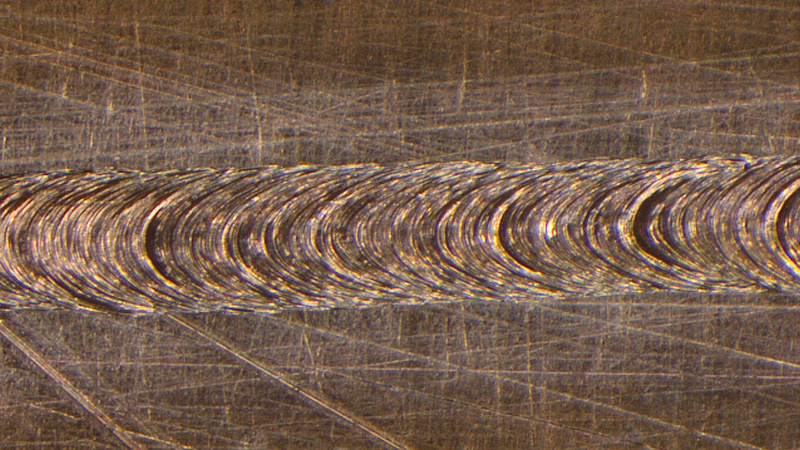

Copper has only been suitable for laser welding for the past few years. This slow development is due to copper’s high thermal conductivity, and in particular to its low absorption of laser radiation. Because of these difficulties, welding copper requires a high beam quality for the benefit of high intensities. Only high intensities ensure that the laser radiation can be reliably coupled to the material.

With this in mind, single-mode fibre lasers or high-power lasers from about 5 kW, or a focal diameter of 200 µm, are preferred. In order to achieve the weld qualitiy required when laser welding copper, advanced technologies for beam guidance and shaping are also important.

When laser welding copper, it is important to remember that the deep-penetration effect is much more pronounced than with other materials. This is because before the threshold is reached, a high proportion of the laser power continues to be reflected, whereas once the threshold has been reached, the molten bath absorbs almost all of the laser radiation. This means that only a narrow ridge runs between a superficial thermal conduction weld and a deep weld seam. This is difficult to adjust, making it hard to precisely set a shallow welding penetration depth.

Copper welding is mainly used for functional conductive components – for example, stranded wires, battery components and connectors.