Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

Recent years have seen great advances in influencing the shape of a laser beam. These advances have now made their way into industrial laser material processing – and thus also into laser welding – redefining the boundaries of what is possible with lasers. Speed and quality optimisation due to improved shapes in the melt pool and the capillary are convincing arguments for advanced beam shaping technology. In this respect, beam shaping technology is preferred for materials that typically present problems in laser welding.

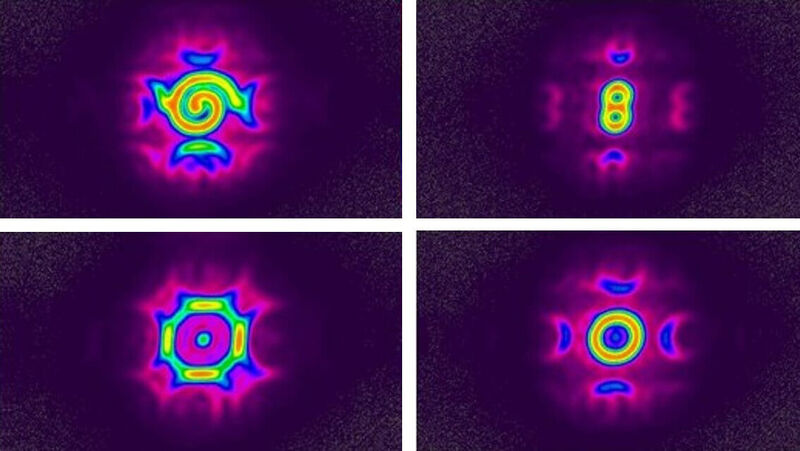

Beam shaping technology is the spatial and/or temporal distribution of intensity and control of the laser beam. The laser beam itself provides the reference.

Today, numerous laser manufacturers allow for statically targeted intensity distribution. The power of the laser beam source can be distributed to the core and the ring of the fibre optic cable. Using a wobble head to “wobble” the laser beam offers additional, flexible options for both scanner welding and fixed optic welding. Both methods are considered spatial beam shaping.

For several years, temporal beam shaping has been used with Nd:YAG lasers by means of pulsing laser radiation and influencing the temporal intensity distribution within individual laser pulses. Modern cw beam sources can also lead to the generation of pulsed laser beams. Both metallurgical and thermal pulse shaping can have a positive effect on the mixing and solidification of a melt.

Dynamic beam shaping technology is innovative when compared to existing beam shaping possibilities. The goal is primarily spatial beam shaping, but it can achieve this up to 10,000 times faster than was possible with previous technologies. The main goal when applying dynamic beam shaping is to precisely adjust to the capillary shape best suited to the weld.

The many advantages of beam shaping are especially relevant for aluminium and copper, and therefore for the e-mobility sector. For example, using beam shaping can precisely influence the mixing ratio of the parts to be joined.