Fax: (0 80 36) 9 08 20- 28

E-Mail: info@bbw-lasertechnik.de

Gewerbering 11

83134 Prutting

The reasons for using aluminum are the favorable ratio of weight to mechanical properties, but also its electrical conductivity and thermal conductivity. Therefore, joining processes for aluminum are becoming increasingly important in industrial applications. Advances in laser technology mean that the highest requirements can be met by laser welding. A large number of applications for laser welding of aluminum can be found in e-mobility in particular.

In principle, aluminum can be welded well. However, low-alloyed aluminum materials tend to hot cracking. High-alloy aluminum materials, on the other hand, tend to eject due to magnesium evaporation. Aluminum is also relevant as a material for laser-welded mixed joints.

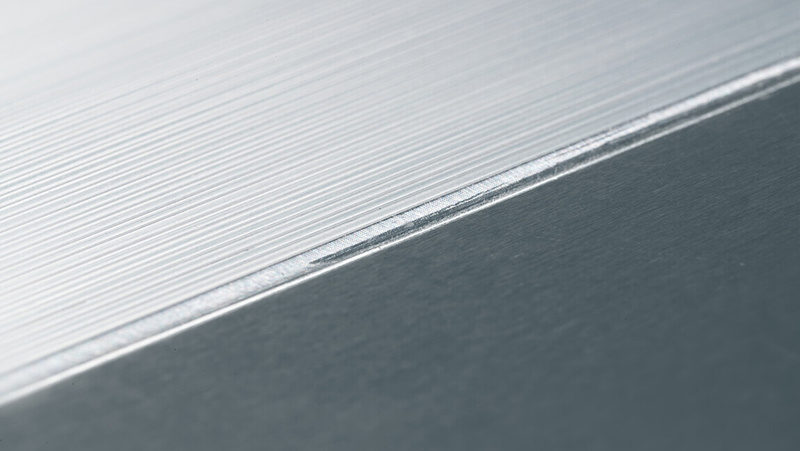

Laser welding of aluminum has been established for some time, but in the past was characterized by an increased susceptibility to pores. New possibilities of beam guidance - i.e. faster welding - as well as beam shaping have significantly increased the achievable welding qualities. In addition, today's higher beam qualities have a positive influence on aluminum welding. Therefore, new applications for laser welding of aluminum are emerging today. Against this background, BBW Lasertechnik is conducting intensive research on laser welding processes for aluminum materials .

With the use of the latest technology, aluminum die casting can also be laser welded - even with high requirements for tightness, as is the case in the electrical and electronics sector. Until recently, this was considered impossible or only conditionally weldable.

Direct advantages are slimmer seams with lower susceptibility to cracking, which make laser welding of aluminum possible without additional material. Another factor is the consideration of a design suitable for production, for example to reduce susceptibility to cracking using fillet welds.

Since the process window for laser welding of aluminum is smaller than for materials that are easier to weld, it is important to create consistent conditions. A fundamental factor is the cleanliness of the components and the production environment, as contamination can quickly have a negative effect on the quality of the welding processes.

BBW Lasertechnik is able to produce individual parts from aluminum materials - e.g. by laser cutting or by machining processes - and to prepare them for laser welding by means of suitable cleaning processes. In the meantime, laser cleaning has also become established. In addition, we at BBW Lasertechnik use in-process non-destructive and destructive testing, e.g. online process monitoring or micrographs.

Similar to copper, aluminum is used in many current-carrying components, for example in e-mobility. These include power conductors, stranded wires, batteries and connectors. Furthermore, laser welding of aluminum is recommended for the production of cooling plate for various applications. This is because aluminum has high thermal conductivity, and copper is also undesirable in cooling circuits.